Understanding the Differences Between Melt Blown and String Wound Filter Cartridges

When it comes to selecting a filter cartridge, the choice between melt blown and string wound options can be perplexing. Each type of filter has unique characteristics and advantages, making it essential to understand their differences to determine which is best for your application.

What is a Melt Blown Filter Cartridge?

Melt blown filter cartridges are created by melting and extruding polypropylene or similar materials to form a fine, gradient-structured mesh. This construction provides:

- Fine Filtration: Capable of removing particles as small as 1 micron.

- High Dirt-Holding Capacity: Ideal for applications requiring high efficiency and consistent performance.

- Applications: Commonly used in pharmaceuticals, food and beverage, and electronics industries where fine filtration is critical.

What is a String Wound Filter Cartridge?

String wound filter cartridges are made by tightly winding a continuous strand of fiber, such as polypropylene, cotton, or nylon, around a central core. This design offers:

- Durability: Able to withstand high temperatures and pressures.

- High Dirt-Holding Capacity: Effective for larger particle filtration, typically ranging from 1 to 50 microns.

- Applications: Frequently used in water treatment, chemical processing, and oil and gas industries.

Key Differences Between Melt Blown and String Wound Filters

Construction

- Melt Blown: Fibers are blown from a nozzle and thermally bonded, creating a dense, porous structure without a support core.

- String Wound: Yarn of specific diameter is wound over a support core, forming a diamond-shaped pattern that provides depth filtration.

Filtration Path and Impingements

- Melt Blown: Offers a nearly straight path with fewer filtration points.

- String Wound: Creates a tortuous, zigzag path with more filtration points, enhancing depth filtration.

Dirt-Holding Capacity and Efficiency

- Melt Blown: Typically lower dirt-holding capacity, suitable for lower concentrations of suspended solids.

- String Wound: Higher dirt-holding capacity, ideal for higher concentrations of suspended solids and pre-filtration applications.

Micron Ratings

- Melt Blown: Usually available in finer micron ratings (1 to 20 microns).

- String Wound: Available in a broader range of micron ratings (0.5 to 150 microns).

Durability and Maintenance

- Melt Blown: May require more frequent replacements, potentially increasing maintenance costs.

- String Wound: Longer service life with higher dirt-holding capacity, reducing the frequency of cartridge replacements and overall maintenance costs.

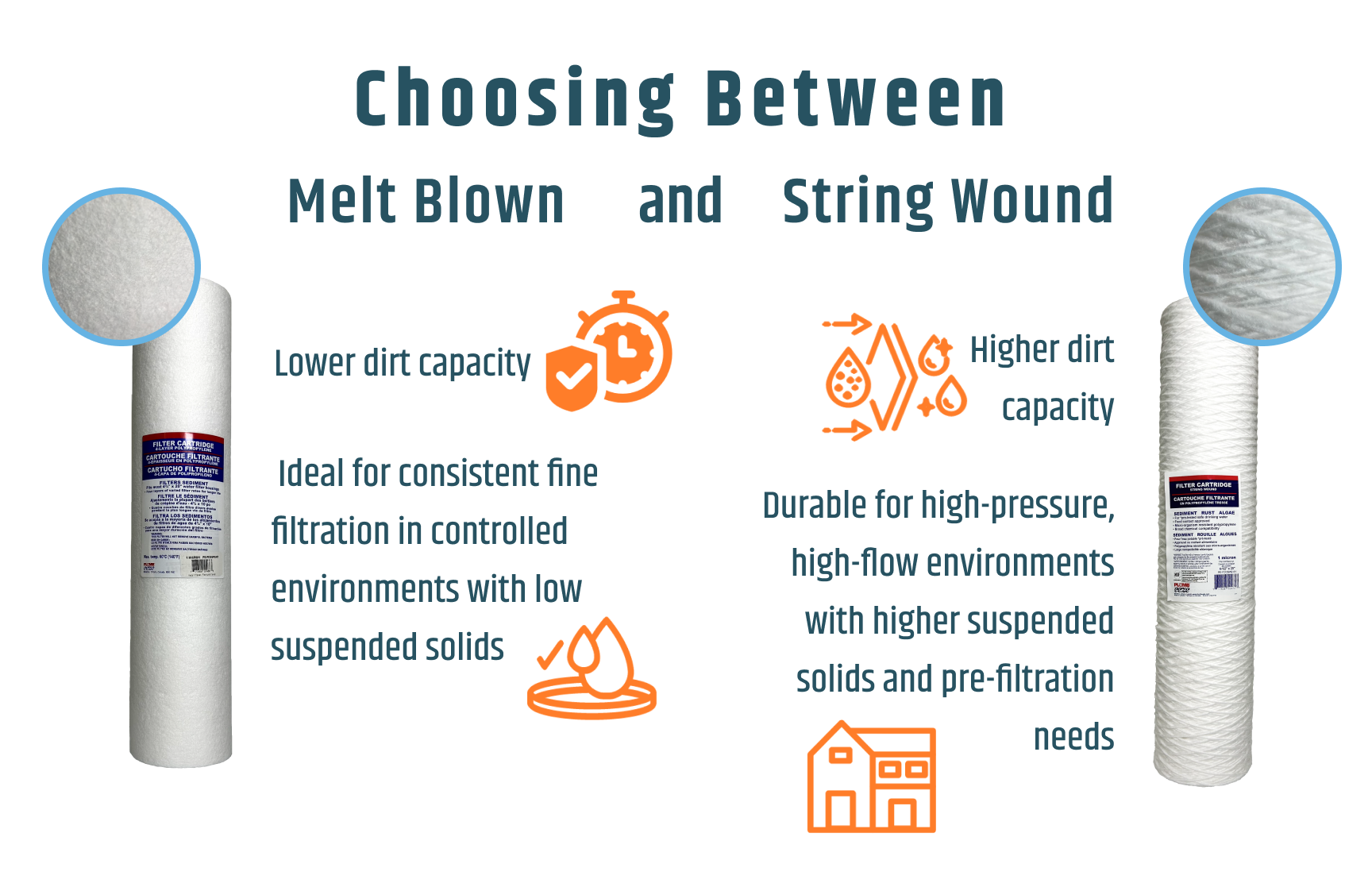

Choosing the Right Filter Cartridge

When selecting between melt blown and string wound filter cartridges, consider the following factors:

Type of Contaminants

- Melt Blown: Best for capturing fine particles and ensuring precise filtration.

- String Wound: Ideal for removing larger particles and handling higher sediment loads.

Application Environment

- Melt Blown: Suitable for controlled environments where consistent, fine filtration is critical.

- String Wound: Robust and durable, suitable for high-pressure and high-flow environments.

Flow Rate and Pressure

- Melt Blown: Works well in systems with moderate flow rates and pressures.

- String Wound: Handles higher flow rates and pressure drops effectively.

Cost and Maintenance

- Melt Blown: Often requires more frequent replacements.

- String Wound: Typically has a longer service life, reducing maintenance costs.

Summary

Choosing between melt blown and string wound filter cartridges depends on your specific filtration needs. Melt blown filters are ideal for applications requiring fine filtration and high efficiency, while string wound filters excel in durability and handling higher sediment loads. By evaluating the type of contaminants, application environment, flow rate, pressure, and maintenance requirements, you can select the filter cartridge that provides optimal performance and efficiency for your needs.

For more information or to explore our range of melt blown and string wound filter cartridges, contact us today.