Categories

- Shop All (4976)

-

-

- Hi-Vis Chainsaw Safety (14)

- Hi-Vis Coveralls and Overalls (10)

- Hi-Vis Hoodies and Shirts (27)

- Hi-Vis Jackets (30)

- Hi-Vis Pants (14)

- Hi-Vis Rain Wear (30)

- Hi-Vis Vests (36)

- Winter Hi-Vis Bombers and Parkas (18)

- Winter Hi-Vis Coveralls and Overalls (18)

- Winter Hi-Vis Hoodies (3)

- Winter Hi-Vis Pants (3)

- Winter Hi-Vis Vests (5)

-

-

-

-

- Brooms (2)

- Dust Mops (0)

- Dust Pans and Brushes (4)

- Flow Thru Tools (2)

- Microfiber Mops (0)

- Pool and Tank Tools (2)

- Scrubbers and Scrapers (1)

- Soap and Sanitizer Dispensers (0)

- Sprayers (1)

- Squeegees (1)

- Toilet Brushes and Plungers (3)

- Trash Cans & Bags (8)

- Wet Floor Signs (0)

- Wet Mops and Buckets (4)

-

- Bars and Prying Tools (21)

- Bolt Cutters and Shears (17)

- Chisels and Punches (9)

- Combination Hand Tool Sets (12)

- Extractors (13)

- Files (6)

- Gear Pullers (14)

- Hammers and Mallets (14)

- Hand Saws (17)

- Hex Keys (12)

- Layout and Distance Lasers (1)

- Marking Tools (0)

- Measuring Tools (10)

- Pliers (52)

- Precision Measuring and Testing Tools (24)

- Propane Torches (5)

- Screwdrivers and Nutdrivers (21)

- Sockets (66)

- Tap and Die Sets (11)

- Tool Boxes (26)

- Utility Knives (14)

- VDE Tools (7)

- Wire Cutters and Strippers (14)

- Wrenches (22)

-

- Beveling and Deburring (17)

- Curb and Valve Keys (20)

- Drilling and Tapping (12)

- Extended Impact Sockets (3)

- Flaring and Rerounding (7)

- General Pipe Working Tools (19)

- Guillotine Pipe Cutters (2)

- Hydrostatic Test Pumps (14)

- Internal Pipe Cutters (6)

- Manhole Testing (4)

- PE Peelers (8)

- Pipe Reamers (4)

- Pipe Threading (17)

- Pipe Wrenches (24)

- Plastic Pipe Joint Kits (4)

- Plastic Pipe Saws (5)

- Power Drive (13)

- Quick Release Cutters (15)

- Ratchet Shears (9)

- Ratcheting Wrenches (12)

- Rotary Cutters (3)

- Shut Off Tools (9)

- Soldering Torches (3)

- Vises (7)

-

- Angle Grinders (6)

- Batteries and Chargers (18)

- Bench Grinders (7)

- Circular Saws (3)

- Combo Tool Kits (10)

- Cordless Fans (6)

- Cordless Lighting (15)

- Cut Off Saws (4)

- Drills and Drivers (8)

- Grease Guns (3)

- Impact Drivers (5)

- Jobsite Radios and Speakers (8)

- Lifestyle (6)

- Mitre Saws (2)

- Reciprocating Saws (4)

-

- Angle Grinder Wheels and Brushes (21)

- Bench Grinder Wheels (7)

- Circular Saw Blades (11)

- Drill and Driver Bits (26)

- High Speed Gas Saw Blades (3)

- Holesaws (11)

- Impact Sockets (25)

- Jig Saw Blades (2)

- Oscillating Multi Tool Blades (1)

- Portable Chop Saw Blades (4)

- Power Tool Storage (5)

- Reciprocating Saw Blades (8)

-

-

-

-

- Air Fresheners (0)

- All Purpose Cleaners (19)

- Bowl and Washroom (8)

- Coffee and Breakroom (19)

- Degreasers (3)

- Dishwashing (4)

- Disinfectants and Sanitizers (1)

- Drain Openers (7)

- Hand Cleaners (8)

- Laundry Cleaners (9)

- Paper Products and Wiper Rags (18)

- Scale Removers (4)

- Urinal Pucks and Liquids (5)

- Wet Wipes (2)

-

-

- Ball Valves (13)

- Black and Galvanized Steel Fittings (16)

- Bronze Pipe Fittings and Nipples (13)

- Butterfly Valves (4)

- Check Valves (18)

- Flexible Connectors (4)

- Gate and Globe Valves (5)

- Knife Gate Valves (9)

- Pipe Fitting Accessories (4)

- Schedule 80 PVC Fittings (27)

- Stainless Steel Fittings and Valves (24)

- Victaulic Grooved Fittings (22)

Drum Drain Cleaning Machines

12 products

Showing 1 - 12 of 12 products

Drum drain cleaning machines are professional tools designed to clear tough blockages in sewer and drain lines using a rotating cable housed inside a drum. Built for plumbers, maintenance crews, and municipal operations, these machines handle grease, roots, and debris in residential, commercial, and industrial piping systems.

Shop professional drum drain cleaning machines engineered for power, durability, and dependable performance, available from Cleanflow.

✔ Professional-grade equipment

✔ Replacement parts available

✔ Canadian warehouse & support

✔ Free shipping on orders over $199

How to Choose a Drum Drain Cleaning Machine

Choosing the right drum drain cleaner depends on the type of work you perform and the pipe sizes you service. Compact machines are ideal for residential and light commercial applications where portability and quick setup are important. Larger, more powerful drain cleaning machines are better suited for commercial and municipal jobs that require longer cables and higher torque to break through roots, grease, and hardened blockages.

When selecting a machine, consider pipe diameter compatibility, cable length and thickness, motor power, and frequency of use.

Electric drum machines are preferred for consistent performance on tougher stoppages, while smaller units are often used by service plumbers working in confined spaces.

Popular Drum Drain Cleaning Machines

Sewerooter Drum Machine

The Sewerooter drum machine is a compact, professional option for clearing 3”–4” drain lines in residential and light commercial applications.

Electric Drum Auger

This electric drum auger offers portability and fast setup, making it well suited for service technicians handling smaller drain lines and routine maintenance work.

Speedrooter Drum Machine

Designed for demanding jobs, the Speedrooter drum machine handles 3”–10” lines with consistent power, making it a dependable choice for commercial drain cleaning.

Maxi-Rooter Drum Machine

For heavy-duty sewer work, the Maxi-Rooter drum machine delivers high torque to cut through roots, grease, and compacted debris in large-diameter lines.

Mini-Rooter Pro

The Mini-Rooter Pro is a versatile solution for plumbers working in tight spaces and smaller drain systems while maintaining professional-grade performance.

Drum Machine Cables, Cutters & Accessories

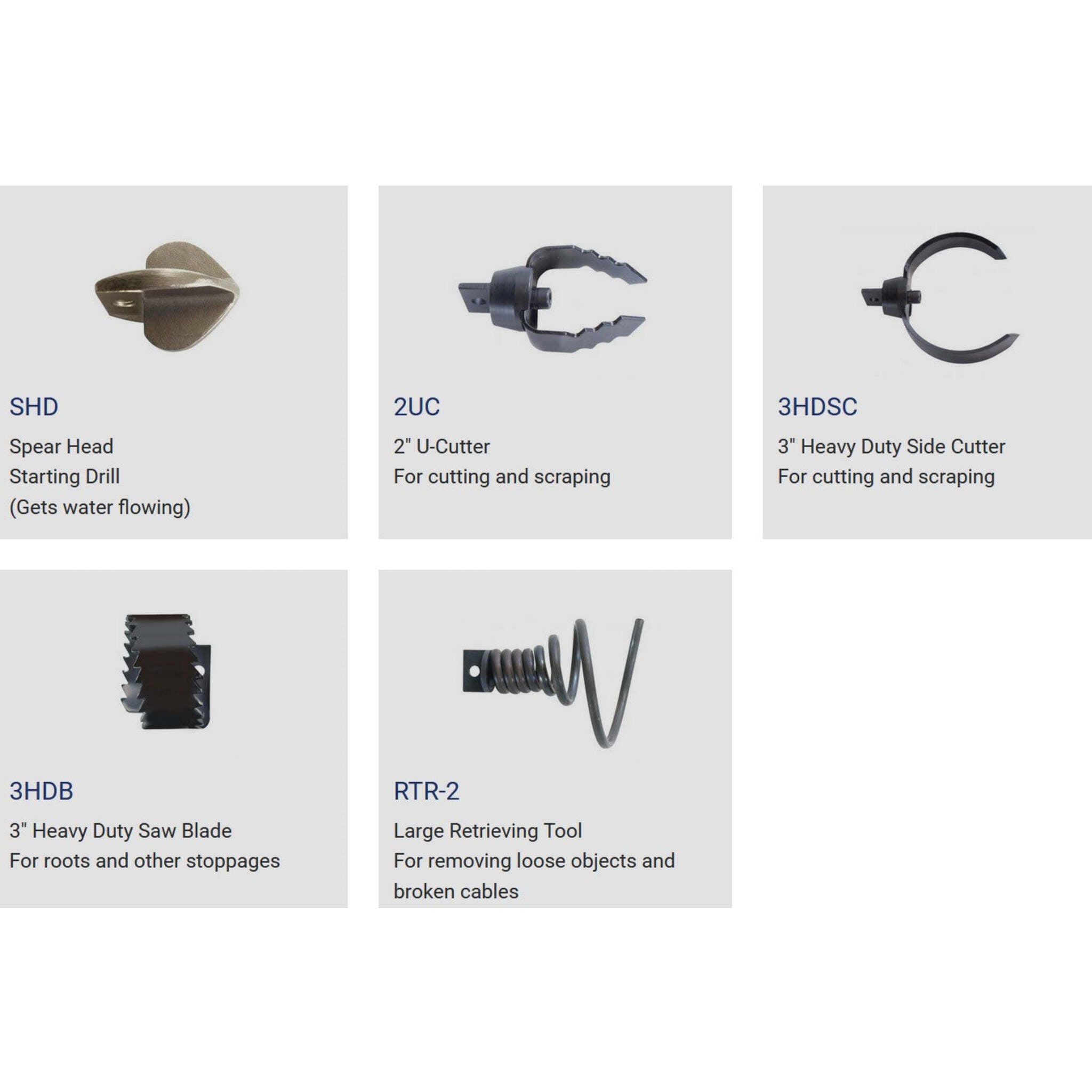

Drum Machine Cutters

A full range of drum machine cutters is available to break up grease, roots, and stubborn obstructions in sewer and drain lines.

Drain Cleaning Cable

High-strength drain cleaning cable is available to replace worn cables or extend the reach of professional drum machines.

Drain Snake Repair Kit

A drain snake repair kit allows for quick field repairs, helping reduce downtime during service calls.

Mini Rooter Cutter Set

The Mini Rooter cutter set is designed specifically for smaller drum machines used in service and maintenance applications.

ClogChopper Cutter

The ClogChopper cutter is effective for breaking up grease and soft blockages while restoring proper flow efficiently.

Safety and Maintenance Tips

-

Always wear appropriate PPE

-

Inspect cables and cutters before use

-

Clean and dry cables after each job

-

Replace damaged components immediately

Routine maintenance keeps drum machines operating safely and efficiently.

Need Help Choosing a Drum Machine?

Not sure which drum drain cleaning machine is right for your application? The team at Cleanflow can help you choose the right equipment based on pipe size, job type, and frequency of use.

We carry trusted professional brands such as General Pipe Cleaners and ToolTech, and support customers across Canada and the United States.

Drum Drain Cleaning Machine FAQs

What Is a Drum Drain Cleaning Machine?

A drum drain cleaning machine is a motorized tool that clears blockages by rotating a flexible cable inside a protective drum. As the cable advances through a drain or sewer line, attached cutters break apart grease, roots, and debris to restore flow.

Unlike handheld augers, drum machines are designed for professional use and can handle longer runs, larger pipe diameters, and more severe obstructions.

Which type of drum drain cleaning machine should I choose?

The right drum drain cleaning machine depends on your typical job requirements. Manual machines are suitable for light-duty residential work, while electric drum machines are recommended for frequent use, larger pipe diameters, and more demanding commercial or municipal applications.

How do you use a drum drain cleaner?

Feed the cable from the drain cleaning drum into the drain opening and slowly advance it while the machine rotates. The rotating cable and attached cutter break apart grease, roots, and debris inside the pipe. Drum drain cleaning machines are designed for controlled, professional operation and should always be used with proper safety equipment and according to manufacturer instructions.

What is the most effective drain cleaner?

For tough blockages, mechanical drum drain cleaning machines are far more effective than chemical drain cleaners. They physically remove grease, roots, and hardened debris rather than dissolving material temporarily, making them the preferred solution for plumbers, commercial facilities, and municipal drain maintenance.

What is the best drain cleaner for severe drain clogs?

The best drain cleaner for severe drain clogs is a large drum drain cleaning machine with sufficient torque and cable length to reach deep blockages. For example, professional machines like the Maxi-Rooter drum machine or Speedrooter drum machine provide the torque, cable capacity, and durability needed to clear deep blockages caused by roots, grease, and compacted debris in demanding environments.

Are drum drain cleaning machines better than chemical drain cleaners?

Yes. Drum drain cleaning machines provide a more effective and long-term solution than chemical drain cleaners. By physically clearing the blockage, drum machines eliminate buildup completely and help maintain pipe integrity.

How long do you leave the drain cleaner in the drain?

Chemical drain cleaners are typically left in the drain for a short period, but they are not recommended for professional or severe clogs. Drum drain cleaning machines immediately clear blockages mechanically, restoring flow safely without relying on corrosive chemicals that can damage pipes.