Categories

- Shop All (4980)

-

-

- Hi-Vis Chainsaw Safety (14)

- Hi-Vis Coveralls and Overalls (10)

- Hi-Vis Hoodies and Shirts (27)

- Hi-Vis Jackets (30)

- Hi-Vis Pants (14)

- Hi-Vis Rain Wear (30)

- Hi-Vis Vests (36)

- Winter Hi-Vis Bombers and Parkas (18)

- Winter Hi-Vis Coveralls and Overalls (18)

- Winter Hi-Vis Hoodies (3)

- Winter Hi-Vis Pants (3)

- Winter Hi-Vis Vests (5)

-

-

-

-

- Brooms (2)

- Dust Mops (0)

- Dust Pans and Brushes (4)

- Flow Thru Tools (2)

- Microfiber Mops (0)

- Pool and Tank Tools (2)

- Scrubbers and Scrapers (1)

- Soap and Sanitizer Dispensers (0)

- Sprayers (1)

- Squeegees (1)

- Toilet Brushes and Plungers (3)

- Trash Cans & Bags (8)

- Wet Floor Signs (0)

- Wet Mops and Buckets (4)

-

- Bars and Prying Tools (21)

- Bolt Cutters and Shears (17)

- Chisels and Punches (9)

- Combination Hand Tool Sets (12)

- Extractors (13)

- Files (6)

- Gear Pullers (14)

- Hammers and Mallets (14)

- Hand Saws (17)

- Hex Keys (12)

- Layout and Distance Lasers (1)

- Marking Tools (0)

- Measuring Tools (10)

- Pliers (52)

- Precision Measuring and Testing Tools (24)

- Propane Torches (5)

- Screwdrivers and Nutdrivers (21)

- Sockets (66)

- Tap and Die Sets (11)

- Tool Boxes (26)

- Utility Knives (14)

- VDE Tools (7)

- Wire Cutters and Strippers (14)

- Wrenches (22)

-

- Beveling and Deburring (17)

- Curb and Valve Keys (20)

- Drilling and Tapping (12)

- Extended Impact Sockets (3)

- Flaring and Rerounding (7)

- General Pipe Working Tools (19)

- Guillotine Pipe Cutters (2)

- Hydrostatic Test Pumps (14)

- Internal Pipe Cutters (6)

- Manhole Testing (4)

- PE Peelers (8)

- Pipe Reamers (4)

- Pipe Threading (17)

- Pipe Wrenches (24)

- Plastic Pipe Joint Kits (4)

- Plastic Pipe Saws (5)

- Power Drive (13)

- Quick Release Cutters (15)

- Ratchet Shears (9)

- Ratcheting Wrenches (12)

- Rotary Cutters (3)

- Shut Off Tools (9)

- Soldering Torches (3)

- Vises (7)

-

- Angle Grinders (6)

- Batteries and Chargers (18)

- Bench Grinders (7)

- Circular Saws (3)

- Combo Tool Kits (10)

- Cordless Fans (6)

- Cordless Lighting (15)

- Cut Off Saws (4)

- Drills and Drivers (8)

- Grease Guns (3)

- Impact Drivers (5)

- Jobsite Radios and Speakers (8)

- Lifestyle (6)

- Mitre Saws (2)

- Reciprocating Saws (4)

-

- Angle Grinder Wheels and Brushes (22)

- Bench Grinder Wheels (7)

- Circular Saw Blades (11)

- Drill and Driver Bits (26)

- High Speed Gas Saw Blades (3)

- Holesaws (11)

- Impact Sockets (25)

- Jig Saw Blades (2)

- Oscillating Multi Tool Blades (1)

- Portable Chop Saw Blades (4)

- Power Tool Storage (5)

- Reciprocating Saw Blades (8)

-

-

-

-

- Air Fresheners (0)

- All Purpose Cleaners (19)

- Bowl and Washroom (8)

- Coffee and Breakroom (19)

- Degreasers (3)

- Dishwashing (4)

- Disinfectants and Sanitizers (1)

- Drain Openers (7)

- Hand Cleaners (8)

- Laundry Cleaners (9)

- Paper Products and Wiper Rags (18)

- Scale Removers (4)

- Urinal Pucks and Liquids (5)

- Wet Wipes (2)

-

-

- Ball Valves (13)

- Black and Galvanized Steel Fittings (16)

- Bronze Pipe Fittings and Nipples (13)

- Butterfly Valves (4)

- Check Valves (18)

- Flexible Connectors (4)

- Gate and Globe Valves (5)

- Knife Gate Valves (9)

- Pipe Fitting Accessories (4)

- Schedule 80 PVC Fittings (27)

- Stainless Steel Fittings and Valves (24)

- Victaulic Grooved Fittings (22)

Marine Hose

6 products

Showing 1 - 6 of 6 products

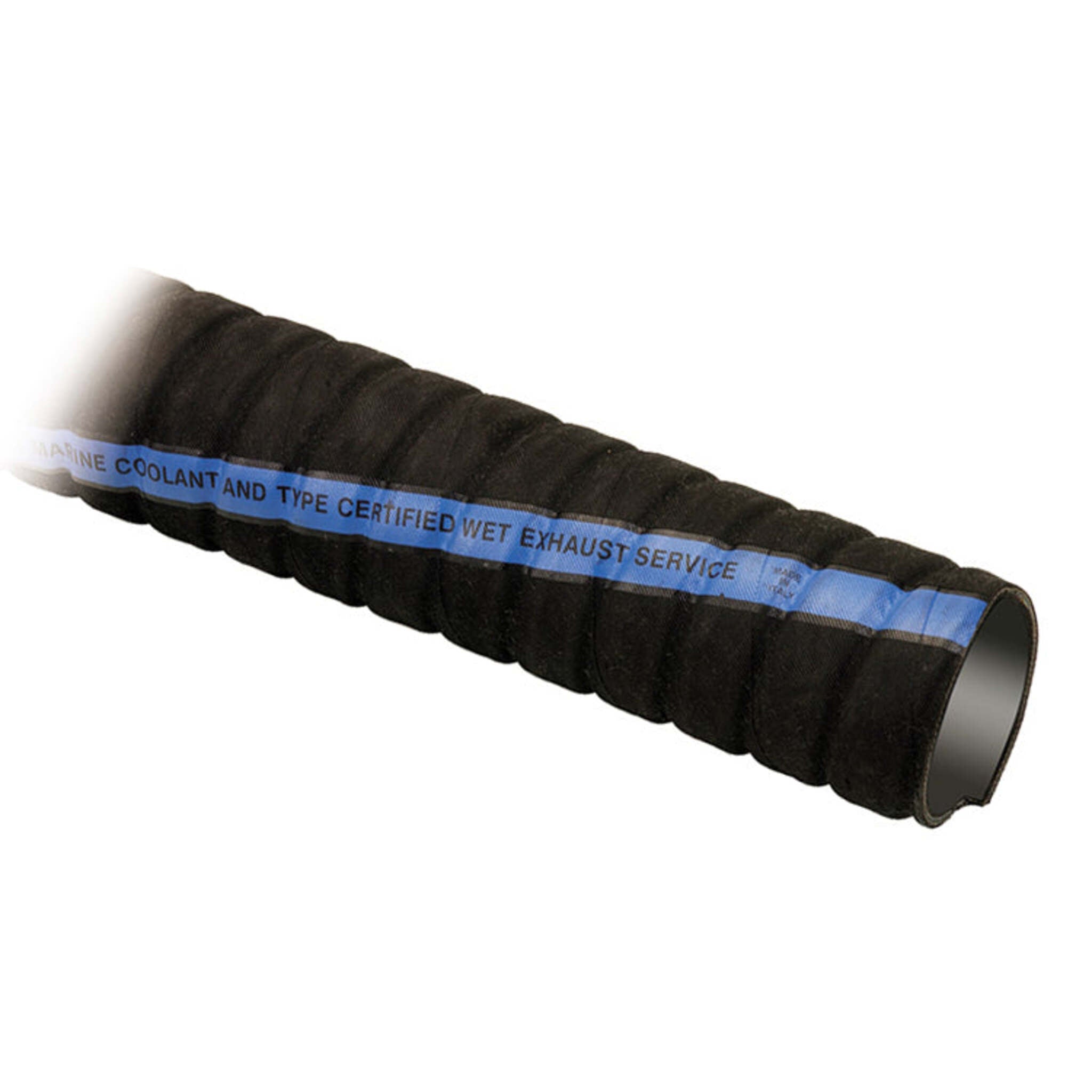

Marine Hose

At Cleanflow, we supply premium Marine Hoses built to endure the harshest marine environments. Whether you're outfitting a recreational boat or a commercial vessel, our marine hoses deliver unmatched reliability for coolant, exhaust, and fuel applications. Designed for flexibility, strength, and superior corrosion resistance, these hoses ensure safety and performance on the water.

Brand History

Our Marine Hose selection is sourced from leading manufacturers known for decades of expertise in marine engineering. These brands have built their reputations by producing hoses that meet and exceed stringent marine industry standards, including SAE J2006 and USCG regulations. With a focus on innovation, durability, and safety, they continue to push boundaries in marine fluid transfer technology.

Why Choose Cleanflow’s Marine Hose Selection?

-

Marine-Grade Durability: Made from tough, corrosion-resistant materials to withstand saltwater, fuel, oils, and harsh chemicals.

-

Flexibility for Tight Spaces: Designed for easy installation, even in cramped engine compartments and around tight bends.

-

Certified Safety: Many hoses meet critical certifications like SAE J2006 R1/R2 and Type A1 USCG, ensuring the highest safety standards for marine use.

-

Wide Range of Applications: Perfect for coolant lines, exhaust systems, and fuel transfer — essential for the reliability and performance of any vessel.

-

Long-Term Reliability: Engineered to resist aging, cracking, and hardening for extended service life in challenging marine environments.

Best-Selling Marine Hoses

-

Greenline

Greenline offers a comprehensive range of high-quality hose and fitting solutions tailored for demanding industrial and commercial applications, including marine environments. Their products are engineered for durability, precision, and reliable fluid and air management, making them an excellent choice for marine hose needs.

-

Corrugated Marine Coolant and Exhaust Hose for Tight Bending Applications

Corrugated Marine Coolant and Exhaust hose is designed for wet exhaust service on marine engines, water intake, and radiator applications. It meets SAE J2006 Type R2 specifications and offers a tighter bend radius due to its corrugated design. The hose is sold per foot, handles temperatures from -40°C to 100°C, and has a working pressure of 60 PSI. It is available in inner diameters ranging from 1-1/2" to 5".

-

Hardwall Marine Coolant and Exhaust Hose

Hardwall Marine Exhaust Hose is designed for wet exhaust service on marine engines, water intake, and radiator applications, meeting SAE J2006 Type R2 specifications. It handles temperatures from -40°C to 100°C and working pressures up to 60 PSI. It is available in inner diameters ranging from 1/2" to 5".

-

Type A1 Marine Fuel Line Hose

Type A1 Marine Fuel Line Hose meets SAE J1527 Type A1 standards, making it suitable for fuel feed lines in enclosed engine compartments. It features a flame-resistant cover and is highly resistant to fuel vapor permeation. Constructed with a nitrile rubber inner tube, spiral synthetic yarn reinforcement, and a weather-resistant rubber outer cover, it operates between -20°C and 95°C. It has varying working pressures depending on the size.

Key Applications of Marine Hoses:

-

Fuel and Oil Transfer: Essential for loading and unloading fuel and oil between ships, shore tanks, and offshore platforms. These hoses are engineered to safely handle hazardous and flammable liquids, often featuring anti-static properties to prevent sparks.

-

Cargo Loading and Unloading: Used for transferring chemicals and food-grade liquids, with specific hoses tailored to each type of cargo to prevent contamination and ensure safety.

-

Ballast and Bilge Operations: Ballast hoses manage the intake and discharge of seawater to maintain vessel stability, while bilge hoses remove unwanted water from the ship’s bilge areas to prevent flooding and corrosion.

-

Sanitation and Waste Transfer: Specialized hoses transport waste and sewage, designed to resist chemicals and prevent odor permeation.

-

Drinking Water Supply: Potable water hoses from food-grade materials deliver fresh water to ships and offshore platforms while preventing contamination.

-

Firefighting: Fire hoses are critical for onboard fire suppression and are designed to withstand high pressure and temperature.

-

Dredging Operations: Hoses move sediments and sand during harbor maintenance or construction projects, built to resist abrasion.

FAQs

1. What certifications should I look for in a marine hose?

Look for hoses that meet SAE J2006 standards for coolant and exhaust hoses and USCG Type A1 certification for fuel hoses. These certifications ensure the hose can handle marine-specific stresses and safety requirements.

2. What’s the difference between corrugated and hardwall hoses?

Corrugated hoses offer superior flexibility for tight bends and compact spaces, while hardwall hoses provide greater strength and are ideal for straighter or gently curved installations.

3. Can I use a coolant hose for fuel applications?

No. Coolant and exhaust hoses are designed for water and exhaust gases. In contrast, fuel hoses like the Type A1 Marine Fuel Line Hose are designed to handle gasoline and diesel safely without degradation.

4. How often should marine hoses be replaced?

Inspecting marine hoses annually and replacing them every 5 to 7 years or sooner if there are visible signs of wear, cracking, or leaks is recommended.

5. Are these hoses resistant to saltwater and UV exposure?

Yes, all hoses in our marine collection are made from materials that resist saltwater corrosion, UV rays, and ozone exposure for long-lasting performance.

Explore our full range of Marine Hoses today and ensure your vessel runs smoothly and safely, no matter the conditions.