Categories

- Shop All (4980)

-

-

- Hi-Vis Chainsaw Safety (14)

- Hi-Vis Coveralls and Overalls (10)

- Hi-Vis Hoodies and Shirts (27)

- Hi-Vis Jackets (30)

- Hi-Vis Pants (14)

- Hi-Vis Rain Wear (30)

- Hi-Vis Vests (36)

- Winter Hi-Vis Bombers and Parkas (18)

- Winter Hi-Vis Coveralls and Overalls (18)

- Winter Hi-Vis Hoodies (3)

- Winter Hi-Vis Pants (3)

- Winter Hi-Vis Vests (5)

-

-

-

-

- Brooms (2)

- Dust Mops (0)

- Dust Pans and Brushes (4)

- Flow Thru Tools (2)

- Microfiber Mops (0)

- Pool and Tank Tools (2)

- Scrubbers and Scrapers (1)

- Soap and Sanitizer Dispensers (0)

- Sprayers (1)

- Squeegees (1)

- Toilet Brushes and Plungers (3)

- Trash Cans & Bags (8)

- Wet Floor Signs (0)

- Wet Mops and Buckets (4)

-

- Bars and Prying Tools (21)

- Bolt Cutters and Shears (17)

- Chisels and Punches (9)

- Combination Hand Tool Sets (12)

- Extractors (13)

- Files (6)

- Gear Pullers (14)

- Hammers and Mallets (14)

- Hand Saws (17)

- Hex Keys (12)

- Layout and Distance Lasers (1)

- Marking Tools (0)

- Measuring Tools (10)

- Pliers (52)

- Precision Measuring and Testing Tools (24)

- Propane Torches (5)

- Screwdrivers and Nutdrivers (21)

- Sockets (66)

- Tap and Die Sets (11)

- Tool Boxes (26)

- Utility Knives (14)

- VDE Tools (7)

- Wire Cutters and Strippers (14)

- Wrenches (22)

-

- Beveling and Deburring (17)

- Curb and Valve Keys (20)

- Drilling and Tapping (12)

- Extended Impact Sockets (3)

- Flaring and Rerounding (7)

- General Pipe Working Tools (19)

- Guillotine Pipe Cutters (2)

- Hydrostatic Test Pumps (14)

- Internal Pipe Cutters (6)

- Manhole Testing (4)

- PE Peelers (8)

- Pipe Reamers (4)

- Pipe Threading (17)

- Pipe Wrenches (24)

- Plastic Pipe Joint Kits (4)

- Plastic Pipe Saws (5)

- Power Drive (13)

- Quick Release Cutters (15)

- Ratchet Shears (9)

- Ratcheting Wrenches (12)

- Rotary Cutters (3)

- Shut Off Tools (9)

- Soldering Torches (3)

- Vises (7)

-

- Angle Grinders (6)

- Batteries and Chargers (18)

- Bench Grinders (7)

- Circular Saws (3)

- Combo Tool Kits (10)

- Cordless Fans (6)

- Cordless Lighting (15)

- Cut Off Saws (4)

- Drills and Drivers (8)

- Grease Guns (3)

- Impact Drivers (5)

- Jobsite Radios and Speakers (8)

- Lifestyle (6)

- Mitre Saws (2)

- Reciprocating Saws (4)

-

- Angle Grinder Wheels and Brushes (22)

- Bench Grinder Wheels (7)

- Circular Saw Blades (11)

- Drill and Driver Bits (26)

- High Speed Gas Saw Blades (3)

- Holesaws (11)

- Impact Sockets (25)

- Jig Saw Blades (2)

- Oscillating Multi Tool Blades (1)

- Portable Chop Saw Blades (4)

- Power Tool Storage (5)

- Reciprocating Saw Blades (8)

-

-

-

-

- Air Fresheners (0)

- All Purpose Cleaners (19)

- Bowl and Washroom (8)

- Coffee and Breakroom (19)

- Degreasers (3)

- Dishwashing (4)

- Disinfectants and Sanitizers (1)

- Drain Openers (7)

- Hand Cleaners (8)

- Laundry Cleaners (9)

- Paper Products and Wiper Rags (18)

- Scale Removers (4)

- Urinal Pucks and Liquids (5)

- Wet Wipes (2)

-

-

- Ball Valves (13)

- Black and Galvanized Steel Fittings (16)

- Bronze Pipe Fittings and Nipples (13)

- Butterfly Valves (4)

- Check Valves (18)

- Flexible Connectors (4)

- Gate and Globe Valves (5)

- Knife Gate Valves (9)

- Pipe Fitting Accessories (4)

- Schedule 80 PVC Fittings (27)

- Stainless Steel Fittings and Valves (24)

- Victaulic Grooved Fittings (22)

Pipe Threading

17 products

Showing 1 - 17 of 17 products

What is Pipe Threading and Why is it Important?

Pipe threading is a crucial process in plumbing, mechanical work, and industrial applications such as oil and gas. It involves cutting screw-like threads on the ends of pipes to facilitate secure connections and leak-proof seals. This method is widely used to ensure efficiency and durability in fluid and gas transportation systems.

Key Benefits of Pipe Threading

Secure Connections: Threaded pipes form tight joints, preventing leaks in pressurized systems.

Versatility: The threaded design allows compatibility between pipes of different sizes and materials.

Durability: Many threaded pipes are made of corrosion-resistant materials such as stainless steel or brass, extending their lifespan.

Types of Pipe Threaders

Pipe threaders are tools used to create threads on pipes. Depending on the scale of work and application, different types of threaders are available.

1. Manual Pipe Threader

A manual pipe threader is a hand-operated tool designed for small-scale plumbing and construction tasks. It is lightweight, portable, and requires manual force to rotate the die head. Cost-effective and easy to use, it is ideal for occasional or low-volume threading needs.

2. Ratchet Pipe Threader

A ratchet pipe threader is a hand-operated tool designed for efficient pipe threading using a ratcheting mechanism. It works by placing the die head over the pipe end and turning the ratchet handle to cut precise threads, ensuring leak-proof connections. Its design provides better leverage, reducing manual effort and is commonly used for threading small- to medium-sized pipes.

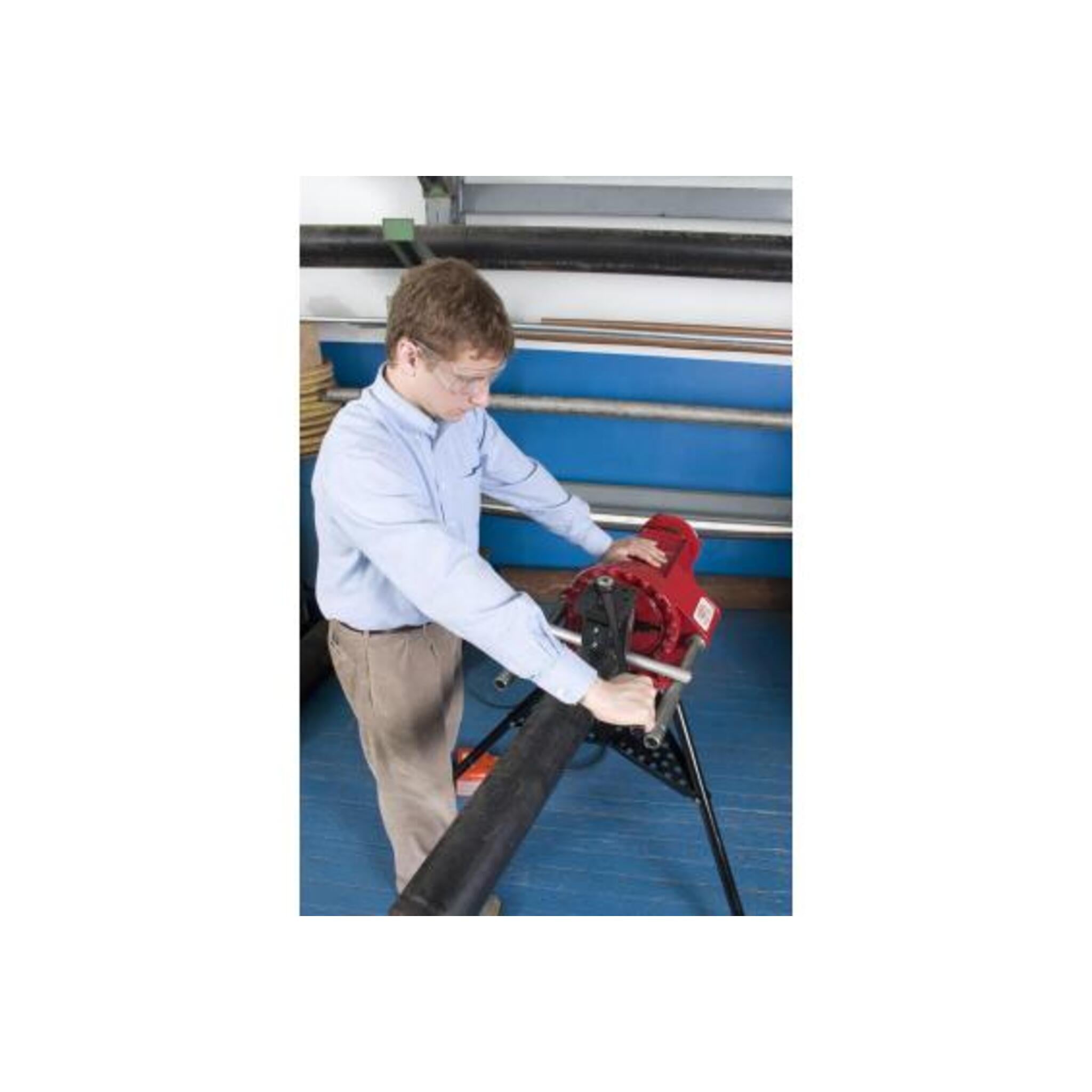

3. Portable Electric Pipe Threader

The portable electric pipe threader is a motor-driven, lightweight tool designed for efficient threading of stainless steel, galvanized steel, copper, and plastic pipes. Featuring automatic feeding, it enables seamless operation without requiring pipe disassembly, even in tight spaces. Ideal for pipeline installation and industrial maintenance, it significantly reduces manual labor and increases threading speed.

4. Mechanical or Industrial Pipe Threader

Mechanical or industrial pipe threaders are heavy-duty, electric- or hydraulic-powered machines designed for high-precision threading of thick-walled pipes. They feature automatic stops to prevent over-threading, ensuring accuracy and efficiency. Commonly used in industries like oil and gas, these machines are essential for large-scale operations requiring durability and precision.

Different Types of Pipe Threads

Threaded pipes generally have two main thread types:

Tapered Threads: These threads narrow toward the end, creating a tighter seal. They are commonly used in plumbing and gas pipelines.

Parallel Threads: These maintain a consistent diameter and are typically used in applications where gaskets are required for sealing.

Explore Pipe Threading Tools at Our Canadian Warehouse

Super Ego Replacement Ratchet Threader Die Sets for Series 600/601

The Super Ego Ratchet Threader Die Sets are precision-engineered for seamless compatibility with Super Ego Series 600/601 Enclosed Ratchets, ensuring flawless operation. This genuine OEM replacement set includes four durable dies, designed for longevity and consistent threading accuracy. With effortless installation and superior reliability, these die sets enhance efficiency, making them an essential upgrade for any threading project.

Reed Enclosed Pipe Threader Dropheads

Reed Enclosed Pipe Threader Dropheads offer seamless compatibility with various threading tools, including the Reed 601PD power drive and multiple major brands. Designed for NPT threading, these enclosed, disposable dropheads eliminate the need for die replacements while ensuring ease of use and minimal maintenance. Their universal adaptability makes them ideal for plumbers, pipefitters, and maintenance professionals looking for a reliable and efficient threading solution.

Super Ego Pipe Threader Drop Heads with Dies for Series 600/601

The Super Ego Pipe Threader Drop Heads with Dies offer precision, durability, and reliability for professional plumbing tasks. Designed for Super Ego Series 600/601 ratchet threader handles, these genuine OEM replacement parts ensure a perfect fit and long-lasting performance. Each drop head comes pre-installed with threader dies for immediate use, making them ideal for replacing worn-out parts or assembling a custom set.

FAQs

How do I determine the right pipe support for my application?

The right pipe support depends on factors such as pipe size, material, load capacity, and environmental conditions. Consider whether the system needs vertical or horizontal stability, vibration control, or thermal expansion management to select the most suitable support.

What are the consequences of using the wrong pipe support?

Using incorrect supports can lead to misalignment, excessive stress, vibrations, and eventual system failure. This can cause leaks, costly repairs, and even safety hazards in industrial settings.

How often should pipe supports be inspected?

Regular inspections should be conducted at least annually or as specified by industry regulations. Frequent checks are necessary in high-vibration environments or where temperature fluctuations affect pipe stability.

Can I mix different types of pipe supports in a single system?

Yes, combining supports like riser clamps for vertical stability and clevis hangers for sloped pipes ensures a balanced, secure installation. However, ensure material compatibility and load distribution to prevent weak points.

How does temperature affect pipe supports?

Extreme temperatures cause pipes to expand or contract, which can stress supports. Flexible supports or expansion joints help accommodate these movements to prevent damage.