Categories

- Shop All (4976)

-

-

- Hi-Vis Chainsaw Safety (14)

- Hi-Vis Coveralls and Overalls (10)

- Hi-Vis Hoodies and Shirts (27)

- Hi-Vis Jackets (30)

- Hi-Vis Pants (14)

- Hi-Vis Rain Wear (30)

- Hi-Vis Vests (36)

- Winter Hi-Vis Bombers and Parkas (18)

- Winter Hi-Vis Coveralls and Overalls (18)

- Winter Hi-Vis Hoodies (3)

- Winter Hi-Vis Pants (3)

- Winter Hi-Vis Vests (5)

-

-

-

-

- Brooms (2)

- Dust Mops (0)

- Dust Pans and Brushes (4)

- Flow Thru Tools (2)

- Microfiber Mops (0)

- Pool and Tank Tools (2)

- Scrubbers and Scrapers (1)

- Soap and Sanitizer Dispensers (0)

- Sprayers (1)

- Squeegees (1)

- Toilet Brushes and Plungers (3)

- Trash Cans & Bags (8)

- Wet Floor Signs (0)

- Wet Mops and Buckets (4)

-

- Bars and Prying Tools (21)

- Bolt Cutters and Shears (17)

- Chisels and Punches (9)

- Combination Hand Tool Sets (12)

- Extractors (13)

- Files (6)

- Gear Pullers (14)

- Hammers and Mallets (14)

- Hand Saws (17)

- Hex Keys (12)

- Layout and Distance Lasers (1)

- Marking Tools (0)

- Measuring Tools (10)

- Pliers (52)

- Precision Measuring and Testing Tools (24)

- Propane Torches (5)

- Screwdrivers and Nutdrivers (21)

- Sockets (66)

- Tap and Die Sets (11)

- Tool Boxes (26)

- Utility Knives (14)

- VDE Tools (7)

- Wire Cutters and Strippers (14)

- Wrenches (22)

-

- Beveling and Deburring (17)

- Curb and Valve Keys (20)

- Drilling and Tapping (12)

- Extended Impact Sockets (3)

- Flaring and Rerounding (7)

- General Pipe Working Tools (19)

- Guillotine Pipe Cutters (2)

- Hydrostatic Test Pumps (14)

- Internal Pipe Cutters (6)

- Manhole Testing (4)

- PE Peelers (8)

- Pipe Reamers (4)

- Pipe Threading (17)

- Pipe Wrenches (24)

- Plastic Pipe Joint Kits (4)

- Plastic Pipe Saws (5)

- Power Drive (13)

- Quick Release Cutters (15)

- Ratchet Shears (9)

- Ratcheting Wrenches (12)

- Rotary Cutters (3)

- Shut Off Tools (9)

- Soldering Torches (3)

- Vises (7)

-

- Angle Grinders (6)

- Batteries and Chargers (18)

- Bench Grinders (7)

- Circular Saws (3)

- Combo Tool Kits (10)

- Cordless Fans (6)

- Cordless Lighting (15)

- Cut Off Saws (4)

- Drills and Drivers (8)

- Grease Guns (3)

- Impact Drivers (5)

- Jobsite Radios and Speakers (8)

- Lifestyle (6)

- Mitre Saws (2)

- Reciprocating Saws (4)

-

- Angle Grinder Wheels and Brushes (21)

- Bench Grinder Wheels (7)

- Circular Saw Blades (11)

- Drill and Driver Bits (26)

- High Speed Gas Saw Blades (3)

- Holesaws (11)

- Impact Sockets (25)

- Jig Saw Blades (2)

- Oscillating Multi Tool Blades (1)

- Portable Chop Saw Blades (4)

- Power Tool Storage (5)

- Reciprocating Saw Blades (8)

-

-

-

-

- Air Fresheners (0)

- All Purpose Cleaners (19)

- Bowl and Washroom (8)

- Coffee and Breakroom (19)

- Degreasers (3)

- Dishwashing (4)

- Disinfectants and Sanitizers (1)

- Drain Openers (7)

- Hand Cleaners (8)

- Laundry Cleaners (9)

- Paper Products and Wiper Rags (18)

- Scale Removers (4)

- Urinal Pucks and Liquids (5)

- Wet Wipes (2)

-

-

- Ball Valves (13)

- Black and Galvanized Steel Fittings (16)

- Bronze Pipe Fittings and Nipples (13)

- Butterfly Valves (4)

- Check Valves (18)

- Flexible Connectors (4)

- Gate and Globe Valves (5)

- Knife Gate Valves (9)

- Pipe Fitting Accessories (4)

- Schedule 80 PVC Fittings (27)

- Stainless Steel Fittings and Valves (24)

- Victaulic Grooved Fittings (22)

Water Jetting Machines

16 products

Showing 1 - 16 of 16 products

Introduction to Water Jetting Machines

Water jetting machines are vital tools in various industries due to their versatility and efficiency. They are specially designed to use pressurized water for different applications like cleaning and cutting. Water jetting machines are renowned for their effectiveness, being able to remove stubborn dirt, grease, or even cutting through hard materials without causing damage to the underlying surface.

Purpose and Use of Water Jetting Machines

These machines provide an environmentally friendly and safe method for industrial cleaning or cutting. In cleaning, they can easily handle tasks from unclogging drains to removing paint from walls. In cutting, they are used in industries like mining and construction to cut through stone, steel, or other hard materials.

Importance in Various Industries

Water jetting machines are critical in various sectors, such as manufacturing, construction, mining, and even in the municipal sector where they are used for sewer cleaning. They offer a non-abrasive, non-toxic, and highly effective method of cleaning or cutting, making them indispensable tools.

History and Evolution of Water Jetting Machines

Understanding the evolution of water jetting machines gives us a glimpse into how far we've come in technology and design.

Initial Designs and Their Limitations

The concept of using water for cutting dates back to the 1950s. However, the initial designs were limited by the technology of their time. They were not as powerful, efficient, or versatile as the machines we have today.

Technological Advancements and Modern Designs

Thanks to advances in technology, modern water jetting machines are more efficient, powerful, and versatile. They feature high-pressure pumps and specially designed nozzles that can handle an array of tasks, from delicate cleaning jobs to cutting through solid rock or metal.

Understanding the Mechanism of Water Jetting Machines

Water jetting machines operate based on a simple but effective mechanism.

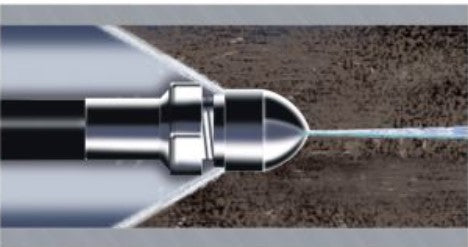

Principle of Operation

The machine works by pressurizing water and then expelling it through a nozzle. The high-pressure water stream is strong enough to clean or cut through materials.

Key Components and Their Functions

There are several key components that contribute to the machine's operation:

High-Pressure Pump

This component is the heart of the machine. It pressurizes the water to the desired level.

Nozzle

The nozzle is responsible for directing the pressurized water onto the target. It is often made of hard materials to withstand the high pressure.

Water Jetting Hose

The hose delivers the high-pressure water from the pump to the nozzle. It must be strong enough to handle the intense pressure without bursting.

Types of Water Jetting Machines

There are mainly two types of water jetting machines based on their pressure levels: high-pressure and ultra-high-pressure machines.

High-Pressure Water Jetting Machines

These machines operate with pressures typically up to 10,000 PSI. They are ideal for tasks like drain cleaning and paint removal.

Ultra-High-Pressure Water Jetting Machines

These machines can achieve pressures exceeding 10,000 PSI, making them suitable for heavy-duty tasks like concrete demolition or cutting through steel.

Applications of Water Jetting Machines

Water jetting machines have diverse applications due to their effectiveness and versatility.

Cleaning Applications

They can be used to clean various surfaces, from clogged drains and sewers to removing grime and paint from walls or floors.

Cutting Applications

Water jetting machines are also used in industries like mining and construction to cut through hard materials like stone or metal. The advantage is that they do not generate heat, thus minimizing the risk of altering or damaging the material being cut.

Selecting a Water Jetting Machine: Factors to Consider

Several factors should be considered when choosing a water jetting machine:

Pressure and Flow Rate: These determine the machine's power and effectiveness. The right pressure and flow rate depend on the specific task at hand.

Quality of Components: High-quality components ensure the machine's durability, efficiency, and safety.

Safety Features: Features like pressure relief valves, shutoff switches, and sturdy housings are crucial for safe operation.

Safety Measures for Using Water Jetting Machines

Like any other industrial equipment, safety is paramount when using water jetting machines.

Personal Protective Equipment: Operators should wear protective gear, including gloves, safety glasses, and sturdy footwear to protect against potential hazards.

Safe Operating Procedures: Operators should be trained in safe operating procedures to avoid accidents and injuries.

Regular Inspections: Regular equipment inspections can help detect any potential issues early, ensuring the machine operates safely and efficiently.

Maintenance and Troubleshooting of Water Jetting Machines

Maintenance and troubleshooting are crucial to ensure the longevity and efficiency of the machine.

Regular Check-ups and Cleaning

Regular maintenance checks and cleaning are necessary to keep the machine running smoothly. This includes checking the pump, hoses, and nozzle for any signs of wear or damage.

Common Problems and Solutions

Common issues include leaks, blockages, and reduced pressure. Operators should be trained to troubleshoot and resolve these issues to avoid downtime.

The Future of Water Jetting Technology

The future of water jetting technology is promising, with advancements aimed at improving efficiency, versatility, and safety. We can expect to see more automated systems, higher pressure capacities, and more sustainable designs.

Conclusion

Water jetting machines are versatile, efficient, and crucial in various industries. With an understanding of their mechanism, types, and applications, it becomes clear why these machines are so indispensable. Their future looks promising, as technology continues to evolve and enhance their capabilities.

Water jetting machines are mainly used for cleaning and cutting applications in various industries. The machine works by pressurizing water and expelling it through a nozzle. The high-pressure water stream can clean or cut through materials. Factors to consider include pressure and flow rate, quality of components, and safety features. Safety measures include using personal protective equipment, adhering to safe operating procedures, and conducting regular equipment inspections. Maintenance requirements include regular check-ups and cleaning, along with troubleshooting and resolving common problems.FAQs

What are the main uses of water jetting machines?

How does a water jetting machine work?

What factors should be considered when choosing a water jetting machine?

What safety measures should be taken when using a water jetting machine?

What are the maintenance requirements of water jetting machines?