Categories

- Shop All (5894)

-

-

- Hi-Vis Chainsaw Safety (14)

- Hi-Vis Coveralls and Overalls (28)

- Hi-Vis Hoodies and Shirts (45)

- Hi-Vis Jackets (38)

- Hi-Vis Pants (22)

- Hi-Vis Rain Wear (48)

- Hi-Vis Vests (53)

- Winter Hi-Vis Bombers and Parkas (24)

- Winter Hi-Vis Coveralls and Overalls (23)

- Winter Hi-Vis Hoodies (4)

- Winter Hi-Vis Pants (4)

- Winter Hi-Vis Vests (6)

-

- Bib Overalls (11)

- Bombers and Parkas (17)

- Coveralls and Overalls (18)

- Disposable Garments (11)

- Flannel and Plaid Work Shirts (22)

- Heated Work Wear (5)

- Hoodies and Sweaters (13)

- Industrial Rainwear (49)

- Pants and Shorts (68)

- Shirts and Sweaters (35)

- Thermal Underwear (44)

- Vests (18)

- Work Jackets (74)

-

-

-

-

- Brooms (0)

- Dust Mops (0)

- Dust Pans and Brushes (0)

- Flow Thru Tools (2)

- Microfiber Mops (0)

- Pool and Tank Tools (2)

- Scrubbers and Scrapers (1)

- Soap and Sanitizer Dispensers (0)

- Sprayers (3)

- Squeegees (1)

- Toilet Brushes and Plungers (1)

- Trash Cans & Bags (8)

- Wet Floor Signs (0)

- Wet Mops and Buckets (2)

-

- Bars and Prying Tools (22)

- Bolt Cutters and Shears (16)

- Chisels and Punches (12)

- Combination Hand Tool Sets (12)

- Extractors (12)

- Files (6)

- Gear Pullers (14)

- Hammers and Mallets (15)

- Hand Saws (22)

- Hex Keys (10)

- Layout and Distance Lasers (1)

- Marking Tools (1)

- Measuring Tools (24)

- Pliers (46)

- Precision Measuring and Testing Tools (24)

- Propane Torches (8)

- Screwdrivers and Nutdrivers (23)

- Sockets (60)

- Tap and Die Sets (4)

- Tool Boxes (27)

- Utility Knives (18)

- VDE Tools (7)

- Wire Cutters and Strippers (14)

- Wrenches (21)

-

- Beveling and Deburring (17)

- Curb and Valve Keys (17)

- Drilling and Tapping (11)

- Extended Impact Sockets (3)

- Flaring and Rerounding (7)

- General Pipe Working Tools (23)

- Guillotine Pipe Cutters (2)

- Hydrostatic Test Pumps (8)

- Internal Pipe Cutters (6)

- PE Peelers (8)

- Pipe Reamers (4)

- Pipe Threading (15)

- Pipe Wrenches (20)

- Plastic Pipe Joint Kits (4)

- Plastic Pipe Saws (5)

- Power Drive (6)

- Quick Release Cutters (15)

- Ratchet Shears (6)

- Ratcheting Wrenches (12)

- Rotary Cutters (3)

- Shut Off Tools (9)

- Soldering Torches (3)

- Vises (7)

-

- Angle Grinders (6)

- Batteries and Chargers (18)

- Bench Grinders (8)

- Circular Saws (3)

- Combo Tool Kits (10)

- Cordless Fans (6)

- Cordless Lighting (15)

- Cut Off Saws (4)

- Drills and Drivers (8)

- Grease Guns (3)

- Impact Drivers (5)

- Jobsite Radios and Speakers (9)

- Lifestyle (7)

- Mitre Saws (2)

- Reciprocating Saws (4)

-

- Angle Grinder Wheels and Brushes (23)

- Bench Grinder Wheels (7)

- Circular Saw Blades (11)

- Drill and Driver Bits (27)

- High Speed Gas Saw Blades (3)

- Holesaws (11)

- Impact Sockets (25)

- Jig Saw Blades (2)

- Oscillating Multi Tool Blades (1)

- Portable Chop Saw Blades (4)

- Power Tool Storage (5)

- Reciprocating Saw Blades (8)

-

-

-

-

- Air Fresheners (2)

- All Purpose Cleaners (19)

- Bowl and Washroom (8)

- Coffee and Breakroom (21)

- Degreasers (3)

- Dishwashing (4)

- Disinfectants and Sanitizers (1)

- Drain Openers (7)

- Hand Cleaners (11)

- Laundry Cleaners (10)

- Paper Products and Wiper Rags (24)

- Scale Removers (2)

- Urinal Pucks and Liquids (5)

- Wet Wipes (4)

-

-

- Ball Valves (13)

- Black and Galvanized Steel Fittings (16)

- Bronze Pipe Fittings and Nipples (16)

- Butterfly Valves (4)

- Check Valves (18)

- Flexible Connectors (4)

- Gate and Globe Valves (6)

- Knife Gate Valves (9)

- Pipe Fitting Accessories (5)

- Schedule 80 PVC Fittings (30)

- Stainless Steel Fittings and Valves (40)

- Victaulic Grooved Fittings (22)

Personal Protective Equipment

25 products

Showing 1 - 24 of 25 products

PPE: Protecting You When You Need It Most

Personal Protective Equipment (PPE) plays a crucial role in ensuring workplace safety and protecting individuals from various hazards. Whether it's head protection, eye and face protection, or respiratory protection, PPE serves as a vital barrier between workers and potential dangers. In this article, we will explore the importance of PPE, the different types available, how to select the right PPE, proper use and maintenance guidelines, its significance in different industries, advancements in PPE technology, and more.

Introduction to Personal Protective Equipment (PPE)

Personal Protective Equipment, or PPE, refers to any equipment or clothing specifically designed to protect individuals from workplace hazards. PPE is a vital part of a comprehensive safety program and is intended to minimize the risk of injuries, illnesses, and other adverse health effects.

Importance of PPE in Ensuring Safety

Protection Against Hazards

The primary purpose of PPE is to provide protection against workplace hazards. Whether it's falling objects, chemical splashes, airborne contaminants, or loud noises, PPE acts as a barrier between the worker and potential dangers, reducing the risk of injury or illness.

Compliance with Regulations

Wearing appropriate PPE is often a legal requirement in many industries and jurisdictions. Compliance with these regulations not only ensures personal safety but also helps organizations meet their legal obligations and avoid penalties or legal consequences.

Prevention of Workplace Injuries and Illnesses

PPE plays a critical role in preventing workplace injuries and illnesses. By wearing the right protective equipment, workers can reduce the likelihood of accidents, exposure to harmful substances, or the development of long-term health issues.

Types of PPE

There are various types of PPE available to address specific hazards:

Head Protection

Head protection includes hard hats and helmets, designed to protect against falling objects, electrical hazards, or head injuries caused by impacts or collisions.

Eye and Face Protection

Eye and face protection, such as safety glasses, goggles, or face shields, shield the eyes and face from flying debris, chemicals, or other potential eye hazards.

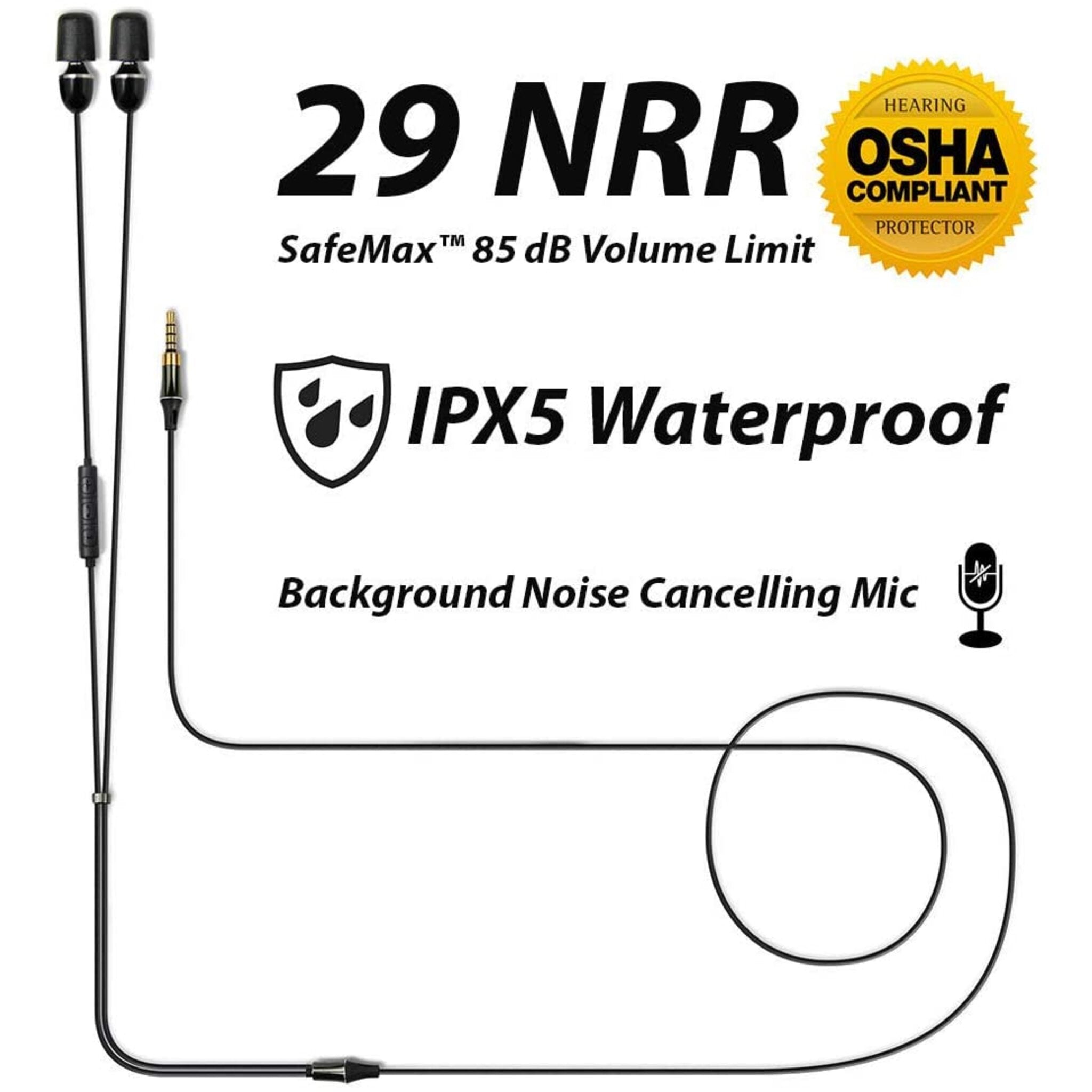

Hearing Protection

Hearing protection, such as earplugs or earmuffs, is designed to reduce exposure to excessive noise levels, preventing noise-induced hearing loss or other auditory damage.

Respiratory Protection

Respiratory protection includes masks, respirators, or self-contained breathing apparatus (SCBA), which protect against airborne contaminants, gases, fumes, or particulates that can be harmful when inhaled.

Hand Protection

Hand protection comprises gloves or gauntlets, offering protection against cuts, burns, chemical exposures, abrasions, or punctures.

Foot Protection

Foot protection includes safety shoes or boots, designed to protect against impact, compression, punctures, or electrical hazards.

Body Protection

Body protection encompasses various garments, such as coveralls, aprons, or vests, providing protection against chemical splashes, biological hazards, or extreme temperatures.

Selecting the Right PPE

Choosing the right PPE is crucial to ensure optimal protection:

Conducting a Hazard Assessment

Before selecting PPE, conduct a thorough hazard assessment of the work environment. Identify the specific hazards workers may encounter to determine the appropriate PPE required for each task.

Understanding PPE Requirements

Understand the requirements and regulations specific to your industry. Familiarize yourself with the standards, guidelines, and recommendations to ensure compliance and proper selection of PPE.

Proper Fit and Comfort

PPE must fit properly to provide adequate protection. Ensure that the PPE is the right size and properly adjusted to the individual's body. Consider the comfort and ergonomics of the equipment to encourage proper use.

Quality and Durability

Choose PPE from reputable manufacturers known for producing high-quality products. Consider durability, as PPE may need to withstand challenging work conditions. Regularly inspect and replace worn-out or damaged equipment.

Proper Use and Maintenance of PPE

Proper use and maintenance of PPE are essential for its effectiveness:

Training and Education

Provide thorough training on the correct use, limitations, and maintenance of PPE. Ensure that workers understand when and how to use the equipment properly.

Regular Inspection and Replacement

Regularly inspect PPE for any signs of wear, damage, or deterioration. Replace damaged or expired equipment promptly to maintain its effectiveness.

Cleaning and Storage

Follow manufacturer guidelines for cleaning and storing PPE. Some equipment may require specific cleaning methods or regular maintenance. Store PPE in a clean and dry environment to prevent contamination or damage.

PPE in Various Industries

PPE is vital in a wide range of industries to protect workers from industry-specific hazards:

Construction and Manufacturing

In construction and manufacturing, PPE is essential for protecting against falling objects, electrical hazards, noise, chemicals, and other dangers present in these industries.

Healthcare and Laboratories

In healthcare settings and laboratories, PPE is crucial for preventing the spread of infections, protecting against biological hazards, and minimizing exposure to chemicals and drugs.

Oil and Gas

In the oil and gas industry, PPE is necessary to protect against the risks associated with drilling, extraction, refining, and transportation, including fire, explosions, and exposure to toxic substances.

Advancements in PPE Technology

Advancements in PPE technology have led to the development of innovative features:

Smart PPE

Smart PPE integrates technology, such as sensors or communication systems, to enhance safety monitoring, data collection, and communication in real-time.

Ergonomic Design

PPE with ergonomic design aims to improve comfort and ease of movement, reducing fatigue and encouraging compliance with PPE usage.

Enhanced Comfort and Breathability

New materials and designs focus on improving comfort and breathability, reducing heat buildup and improving overall user experience.

Conclusion

Personal Protective Equipment (PPE) is a fundamental aspect of workplace safety, providing protection against various hazards. By understanding the importance of PPE, selecting the right equipment, and following proper use and maintenance guidelines, workers can ensure their safety and well-being in the workplace. Whether it's construction, healthcare, or any other industry, PPE is a critical investment in protecting individuals when they need it most.

FAQs

- Can PPE eliminate all workplace hazards?

While PPE is essential in mitigating workplace hazards, it should be used in conjunction with other safety measures. Elimination or reduction of hazards at the source is the most effective approach, and PPE should be considered a last line of defense.

- How often should PPE be replaced?

The replacement frequency of PPE depends on factors such as the type of equipment, manufacturer guidelines, and usage conditions. Regular inspections should be conducted, and PPE should be replaced when it shows signs of wear, damage, or expiration.

- Can PPE be shared among workers?

Ideally, PPE should not be shared among workers, as it may compromise personal hygiene and increase the risk of contamination. Each individual should have their own properly fitted and maintained PPE.

- Are employers responsible for providing PPE?

In most jurisdictions, employers are responsible for providing necessary PPE to employees free of charge. Employers should also ensure that the provided PPE is suitable for the specific hazards of the job.

- Can PPE be reused after decontamination?

Reusable PPE, such as goggles or gloves, can often be decontaminated and reused following proper decontamination procedures. However, disposable PPE, like masks or coveralls, should be disposed of after each use to prevent the spread of contaminants.