Categories

- Shop All (5879)

-

-

- Hi-Vis Chainsaw Safety (14)

- Hi-Vis Coveralls and Overalls (28)

- Hi-Vis Hoodies and Shirts (46)

- Hi-Vis Jackets (37)

- Hi-Vis Pants (22)

- Hi-Vis Rain Wear (48)

- Hi-Vis Vests (53)

- Winter Hi-Vis Bombers and Parkas (24)

- Winter Hi-Vis Coveralls and Overalls (23)

- Winter Hi-Vis Hoodies (4)

- Winter Hi-Vis Pants (4)

- Winter Hi-Vis Vests (6)

-

- Bib Overalls (10)

- Bombers and Parkas (16)

- Coveralls and Overalls (18)

- Disposable Garments (11)

- Flannel and Plaid Work Shirts (22)

- Heated Work Wear (5)

- Hoodies and Sweaters (13)

- Industrial Rainwear (49)

- Pants and Shorts (66)

- Shirts and Sweaters (34)

- Thermal Underwear (44)

- Vests (17)

- Work Jackets (74)

-

-

-

-

- Brooms (0)

- Dust Mops (0)

- Dust Pans and Brushes (0)

- Flow Thru Tools (2)

- Microfiber Mops (0)

- Pool and Tank Tools (2)

- Scrubbers and Scrapers (1)

- Soap and Sanitizer Dispensers (0)

- Sprayers (3)

- Squeegees (1)

- Toilet Brushes and Plungers (1)

- Trash Cans & Bags (9)

- Wet Floor Signs (0)

- Wet Mops and Buckets (4)

-

- Bars and Prying Tools (22)

- Bolt Cutters and Shears (16)

- Chisels and Punches (9)

- Combination Hand Tool Sets (12)

- Extractors (12)

- Files (6)

- Gear Pullers (14)

- Hammers and Mallets (14)

- Hand Saws (22)

- Hex Keys (10)

- Layout and Distance Lasers (1)

- Marking Tools (1)

- Measuring Tools (24)

- Pliers (46)

- Precision Measuring and Testing Tools (24)

- Propane Torches (8)

- Screwdrivers and Nutdrivers (23)

- Sockets (60)

- Tap and Die Sets (4)

- Tool Boxes (27)

- Utility Knives (15)

- VDE Tools (7)

- Wire Cutters and Strippers (14)

- Wrenches (21)

-

- Beveling and Deburring (17)

- Curb and Valve Keys (20)

- Drilling and Tapping (12)

- Extended Impact Sockets (3)

- Flaring and Rerounding (7)

- General Pipe Working Tools (23)

- Guillotine Pipe Cutters (2)

- Hydrostatic Test Pumps (11)

- Internal Pipe Cutters (6)

- PE Peelers (8)

- Pipe Reamers (4)

- Pipe Threading (17)

- Pipe Wrenches (21)

- Plastic Pipe Joint Kits (4)

- Plastic Pipe Saws (5)

- Power Drive (13)

- Quick Release Cutters (15)

- Ratchet Shears (6)

- Ratcheting Wrenches (12)

- Rotary Cutters (3)

- Shut Off Tools (9)

- Soldering Torches (3)

- Vises (7)

-

- Angle Grinders (6)

- Batteries and Chargers (18)

- Bench Grinders (8)

- Circular Saws (3)

- Combo Tool Kits (10)

- Cordless Fans (6)

- Cordless Lighting (15)

- Cut Off Saws (4)

- Drills and Drivers (8)

- Grease Guns (3)

- Impact Drivers (5)

- Jobsite Radios and Speakers (9)

- Lifestyle (7)

- Mitre Saws (2)

- Reciprocating Saws (4)

-

- Angle Grinder Wheels and Brushes (23)

- Bench Grinder Wheels (7)

- Circular Saw Blades (11)

- Drill and Driver Bits (27)

- High Speed Gas Saw Blades (3)

- Holesaws (11)

- Impact Sockets (25)

- Jig Saw Blades (2)

- Oscillating Multi Tool Blades (1)

- Portable Chop Saw Blades (4)

- Power Tool Storage (5)

- Reciprocating Saw Blades (8)

-

-

-

-

- Air Fresheners (2)

- All Purpose Cleaners (19)

- Bowl and Washroom (8)

- Coffee and Breakroom (20)

- Degreasers (3)

- Dishwashing (4)

- Disinfectants and Sanitizers (1)

- Drain Openers (7)

- Hand Cleaners (11)

- Laundry Cleaners (10)

- Paper Products and Wiper Rags (24)

- Scale Removers (4)

- Urinal Pucks and Liquids (5)

- Wet Wipes (4)

-

-

- Ball Valves (14)

- Black and Galvanized Steel Fittings (16)

- Bronze Pipe Fittings and Nipples (16)

- Butterfly Valves (4)

- Check Valves (18)

- Flexible Connectors (4)

- Gate and Globe Valves (6)

- Knife Gate Valves (9)

- Pipe Fitting Accessories (5)

- Schedule 80 PVC Fittings (30)

- Stainless Steel Fittings and Valves (41)

- Victaulic Grooved Fittings (23)

Pressure Gauges

15 products

Showing 1 - 15 of 15 products

Understanding Pressure Gauges

Pressure gauges are critical tools used across industries to measure and monitor the pressure of gases and liquids, ensuring the safe and efficient operation of systems. Available in analog and digital forms, these devices work through mechanical deformation or electronic sensors to provide real-time pressure readings. They are widely used in sectors such as oil and gas, chemical processing, pharmaceuticals, water treatment, and manufacturing. By offering real-time monitoring, equipment protection, and process optimization, pressure gauges enhance system reliability and safety, making them indispensable in industrial operations.

What Are the Different Types of Pressure Gauges?

Pressure gauges come in multiple forms, each designed for specific conditions and applications. Here's a detailed breakdown:

-

Bourdon Tube Gauges are among the most commonly used types. They feature a curved, coiled tube that straightens when pressurized. This movement is mechanically transferred to a needle, which points to the pressure reading on the dial. These gauges are known for their durability and are ideal for high-pressure applications, especially in petrochemical and gas industries.

-

Diaphragm Gauges work using a thin membrane that deflects with pressure changes. These are excellent for low-pressure environments and are resistant to corrosive media, making them well-suited for chemical processing and systems dealing with gaseous substances.

-

Capsule Gauges are designed to detect small pressure differences. They consist of two connected diaphragms forming a capsule, which expands or contracts based on pressure. These gauges are often found in HVAC and ventilation systems where minute pressure measurements are needed.

-

Differential Pressure Gauges measure the difference in pressure between two points within a system. A diaphragm inside the device moves based on the pressure differential. These gauges are critical in filtration systems, refrigeration units, and tank level monitoring where accurate pressure variance tracking is required.

-

Bellows Gauges utilize spring-like metallic tubes that expand or contract under pressure. They’re typically used for low-pressure industrial applications and are known for their sensitivity and accuracy at lower ranges.

-

Digital Pressure Gauges offer precise readings using electronic sensors, such as piezoelectric or strain gauge sensors. These readings are converted into digital values and displayed electronically. They're widely used in laboratories and advanced manufacturing environments where high precision is crucial.

Explore Pressure Gauges at Our Canadian Warehouse

-

4.5" Dry Pressure Gauges with 1/4" Brass Bottom Mount

-

The 4.5" Dry Pressure Gauge with a 1/4" brass bottom mount offers precise, reliable pressure monitoring for general industrial applications. Featuring a large, easy-to-read dial, re-adjustable pointer, and maintenance-free dry design, it ensures accurate readings without the need for liquid filling. Housed in a durable 304 stainless steel case, it withstands harsh environments and operates in temperatures from -40°F to 140°F.

-

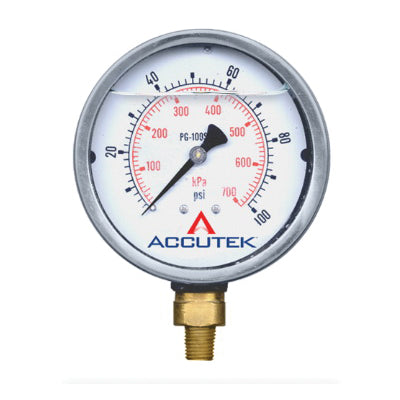

Accutek 4" Dial Liquid Filled Pressure Gauges

-

The Accutek 4" Dial Liquid Filled Pressure Gauges with 1/4" MPT brass bottom mount are designed for precision and durability in demanding environments. Featuring a 304 stainless steel case for corrosion resistance, these gauges offer 1.5% full-scale accuracy and operate within a wide temperature range (-4°F to 140°F). The liquid-filled design minimizes vibration for steadier readings and a longer lifespan. Compliant with ASME B40.100 standards, they are available in pressure ranges from 0–30 PSI to 0–160 PSI, making them suitable for a variety of low to high-pressure applications.

-

4" NSF Rated Liquid Filled Pressure Gauges

-

The 4" NSF Rated Liquid Filled Pressure Gauges feature a durable 304 stainless steel case and a liquid-filled design, which reduces vibration and pulsation for stable readings. The easy-to-read dual-scale dial displays PSI and kPa, with ranges from 0–15 PSI and 0–100 kPa. These gauges offer ±1.5% full-scale accuracy and operate in temperatures from -4°F to 140°F.

FAQs

1. Why does my pressure gauge show zero even when the system is running?

A pressure gauge showing zero while the system is running often indicates a problem with the gauge itself, such as a blockage in the pressure port, a broken internal mechanism, or loss of calibration. It's also possible that there's no pressure being generated due to a system failure, so double-check that your pump or compressor is functioning and that there are no leaks or closed valves in the system.

2. Can a pressure gauge be used for both gas and liquid applications?

Yes, many pressure gauges are designed to work with both gas and liquid, but it's important to ensure the gauge materials are compatible with the specific medium being measured. For example, corrosive liquids or gases may require gauges made of stainless steel or filled with glycerin to avoid damage and ensure accurate readings over time.

3. Why is my pressure gauge needle bouncing or vibrating?

A bouncing or vibrating needle typically indicates pulsating pressure in the system, often caused by reciprocating pumps or compressors. Installing a snubber or using a liquid-filled gauge (like one filled with glycerin or silicone) can dampen these fluctuations, making the needle movement smoother and easier to read accurately.

4. Can I mount a pressure gauge in any orientation?

Not always—many gauges are designed to be read and function best in a vertical position. Liquid-filled gauges, in particular, may give inaccurate readings or show air bubbles in other orientations. Always check the manufacturer’s recommendations for mounting position to maintain accuracy and durability.

5. How often should pressure gauges be calibrated?

Calibration frequency depends on how critical the reading is to your process, but generally, gauges should be calibrated annually. For high-precision or safety-related applications, calibration may be needed every 3 to 6 months, especially in harsh environments or where gauges are frequently exposed to vibration or temperature extremes.