Categories

- Shop All (5888)

-

-

- Hi-Vis Chainsaw Safety (14)

- Hi-Vis Coveralls and Overalls (28)

- Hi-Vis Hoodies and Shirts (45)

- Hi-Vis Jackets (39)

- Hi-Vis Pants (22)

- Hi-Vis Rain Wear (48)

- Hi-Vis Vests (54)

- Winter Hi-Vis Bombers and Parkas (25)

- Winter Hi-Vis Coveralls and Overalls (23)

- Winter Hi-Vis Hoodies (4)

- Winter Hi-Vis Pants (4)

- Winter Hi-Vis Vests (6)

-

- Bib Overalls (11)

- Bombers and Parkas (17)

- Coveralls and Overalls (17)

- Disposable Garments (11)

- Flannel and Plaid Work Shirts (22)

- Heated Work Wear (5)

- Hoodies and Sweaters (12)

- Industrial Rainwear (48)

- Pants and Shorts (70)

- Shirts and Sweaters (34)

- Thermal Underwear (44)

- Vests (18)

- Work Jackets (74)

-

-

-

-

- Brooms (0)

- Dust Mops (0)

- Dust Pans and Brushes (0)

- Flow Thru Tools (2)

- Microfiber Mops (0)

- Pool and Tank Tools (2)

- Scrubbers and Scrapers (1)

- Soap and Sanitizer Dispensers (0)

- Sprayers (3)

- Squeegees (1)

- Toilet Brushes and Plungers (1)

- Trash Cans & Bags (8)

- Wet Floor Signs (0)

- Wet Mops and Buckets (2)

-

- Bars and Prying Tools (22)

- Bolt Cutters and Shears (16)

- Chisels and Punches (12)

- Combination Hand Tool Sets (12)

- Extractors (12)

- Files (6)

- Gear Pullers (14)

- Hammers and Mallets (15)

- Hand Saws (22)

- Hex Keys (10)

- Layout and Distance Lasers (1)

- Marking Tools (1)

- Measuring Tools (24)

- Pliers (46)

- Precision Measuring and Testing Tools (24)

- Propane Torches (8)

- Screwdrivers and Nutdrivers (23)

- Sockets (60)

- Tap and Die Sets (4)

- Tool Boxes (27)

- Utility Knives (17)

- VDE Tools (7)

- Wire Cutters and Strippers (14)

- Wrenches (21)

-

- Beveling and Deburring (17)

- Curb and Valve Keys (17)

- Drilling and Tapping (11)

- Extended Impact Sockets (3)

- Flaring and Rerounding (7)

- General Pipe Working Tools (23)

- Guillotine Pipe Cutters (2)

- Hydrostatic Test Pumps (8)

- Internal Pipe Cutters (6)

- PE Peelers (8)

- Pipe Reamers (4)

- Pipe Threading (15)

- Pipe Wrenches (20)

- Plastic Pipe Joint Kits (4)

- Plastic Pipe Saws (5)

- Power Drive (6)

- Quick Release Cutters (15)

- Ratchet Shears (6)

- Ratcheting Wrenches (12)

- Rotary Cutters (3)

- Shut Off Tools (9)

- Soldering Torches (3)

- Vises (7)

-

- Angle Grinders (6)

- Batteries and Chargers (18)

- Bench Grinders (8)

- Circular Saws (3)

- Combo Tool Kits (10)

- Cordless Fans (6)

- Cordless Lighting (15)

- Cut Off Saws (4)

- Drills and Drivers (8)

- Grease Guns (3)

- Impact Drivers (5)

- Jobsite Radios and Speakers (9)

- Lifestyle (7)

- Mitre Saws (2)

- Reciprocating Saws (4)

-

- Angle Grinder Wheels and Brushes (23)

- Bench Grinder Wheels (7)

- Circular Saw Blades (11)

- Drill and Driver Bits (27)

- High Speed Gas Saw Blades (3)

- Holesaws (11)

- Impact Sockets (25)

- Jig Saw Blades (2)

- Oscillating Multi Tool Blades (1)

- Portable Chop Saw Blades (4)

- Power Tool Storage (5)

- Reciprocating Saw Blades (8)

-

-

-

-

- Air Fresheners (2)

- All Purpose Cleaners (19)

- Bowl and Washroom (8)

- Coffee and Breakroom (21)

- Degreasers (3)

- Dishwashing (4)

- Disinfectants and Sanitizers (1)

- Drain Openers (7)

- Hand Cleaners (11)

- Laundry Cleaners (10)

- Paper Products and Wiper Rags (24)

- Scale Removers (2)

- Urinal Pucks and Liquids (5)

- Wet Wipes (4)

-

-

- Ball Valves (13)

- Black and Galvanized Steel Fittings (16)

- Bronze Pipe Fittings and Nipples (16)

- Butterfly Valves (4)

- Check Valves (18)

- Flexible Connectors (4)

- Gate and Globe Valves (6)

- Knife Gate Valves (9)

- Pipe Fitting Accessories (5)

- Schedule 80 PVC Fittings (32)

- Stainless Steel Fittings and Valves (40)

- Victaulic Grooved Fittings (22)

What are Hydromatic Pumps?

Hydromatic pumps are known for their reliability, efficiency, and durability in handling water and wastewater across residential, municipal, commercial, and industrial applications. Built with robust materials and efficient impeller designs to minimize clogging, they require less maintenance while ensuring long-term performance. These features make Hydromatic pumps a preferred choice for professionals in water management.

Types of Hydromatic Pumps

-

Submersible Sump Pumps

-

Used for drainage in basements and low-lying areas.

-

Ideal for emergency flood water removal.

-

Sewage Sump Pumps

-

Designed to handle wastewater containing solids.

-

Commonly used in sewage basins, septic tank effluent, and dewatering applications.

-

Sewage Ejector Pumps

-

Suitable for situations where gravity drainage is not feasible.

-

Handles larger solids and efficiently removes high volumes of sewage.

-

Condensate Removal Pumps

-

Pumps condensate water from HVAC systems.

-

Capable of handling high temperatures and preventing water damage.

-

Effluent Pumps

-

Pumps greywater from septic tanks to drain fields.

-

Used in high-pressure washing systems and low-traffic waste management.

Discover Hydromatic Pumps at Our Canadian Warehouse

-

Hydromatic VA1 10 Cast Iron Sump Pump

-

The Hydromatic VA1-10 Cast Iron Sump Pump features a vertical mechanical float switch with a piggyback plug for easy manual operation. Built with a cast-iron body and an oil-filled motor, it ensures excellent cooling and longevity, while thermal overload protection prevents overheating. Additional highlights include a carbon-ceramic mechanical shaft seal, single-row ball-bearing construction, and a 10-foot power cord.

-

Hydromatic WA1 10 Submersible Sump Pump

-

The Hydromatic WA1-10 Submersible Cast Iron Sump Pump features a wide-angle float switch for automatic operation, with a piggyback plug for easy manual control. Built with a robust cast iron body and an oil-filled motor for superior cooling, it ensures long-lasting reliability. Additional features include a carbon-ceramic mechanical shaft seal, thermal overload protection, and a single-row ball-bearing construction.

-

Hydromatic SKV50AW1 20-01 Cast Iron Sewage Ejector Pump

-

The Hydromatic SKV50AW1 20-01 Cast Iron Sewage Ejector Pump is designed to efficiently handle 2" solids and stringy materials with minimal clogging. Its heavy-duty cast iron construction, recessed vortex impeller, and oil-filled motor ensure long-lasting reliability, while thermal overload protection safeguards the motor during operation. This 1/2 HP pump delivers a maximum capacity of 80 GPM and a 22-ft head, featuring a piggyback plug float switch for easy maintenance.

FAQs

1. How do I choose the right Hydromatic pump for my needs?

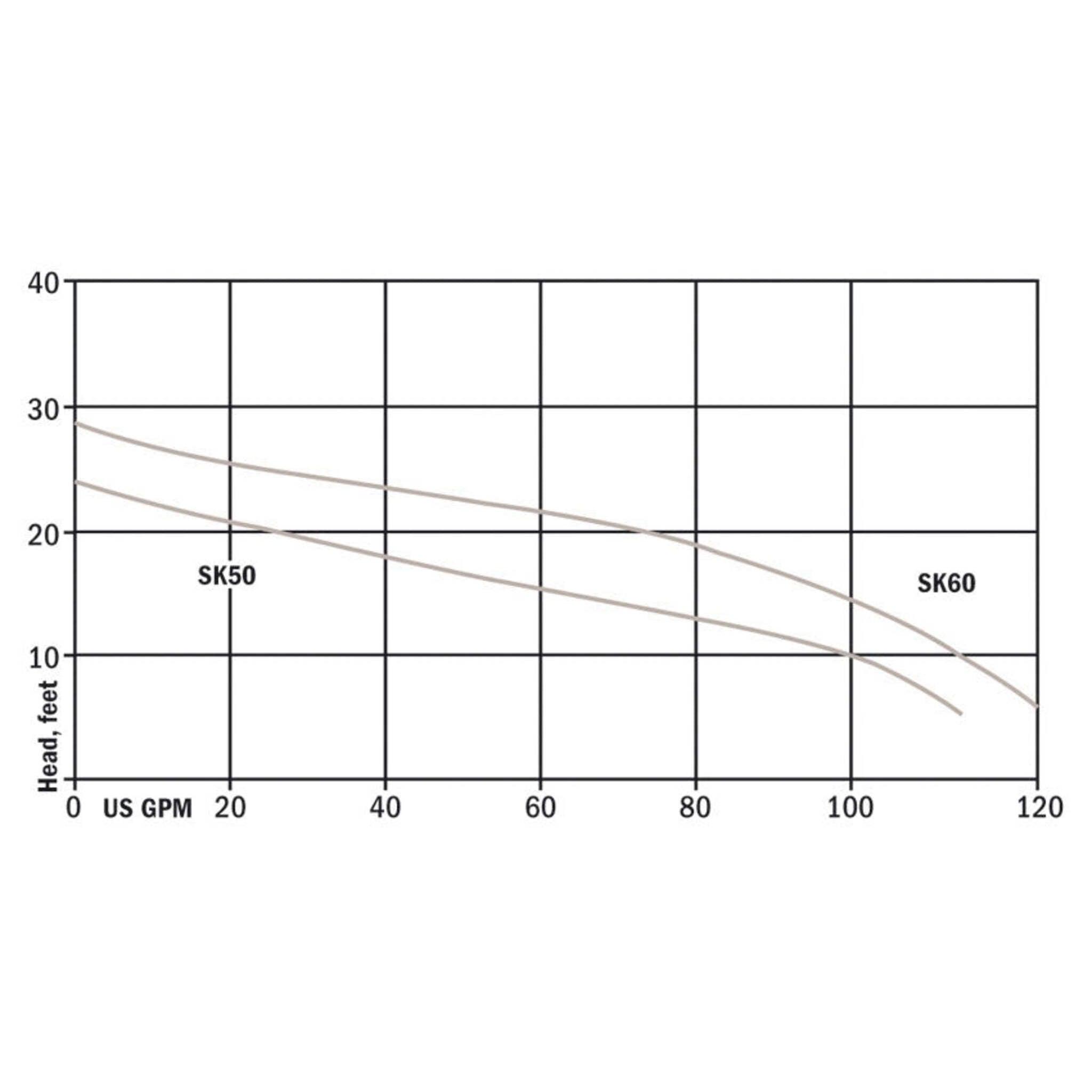

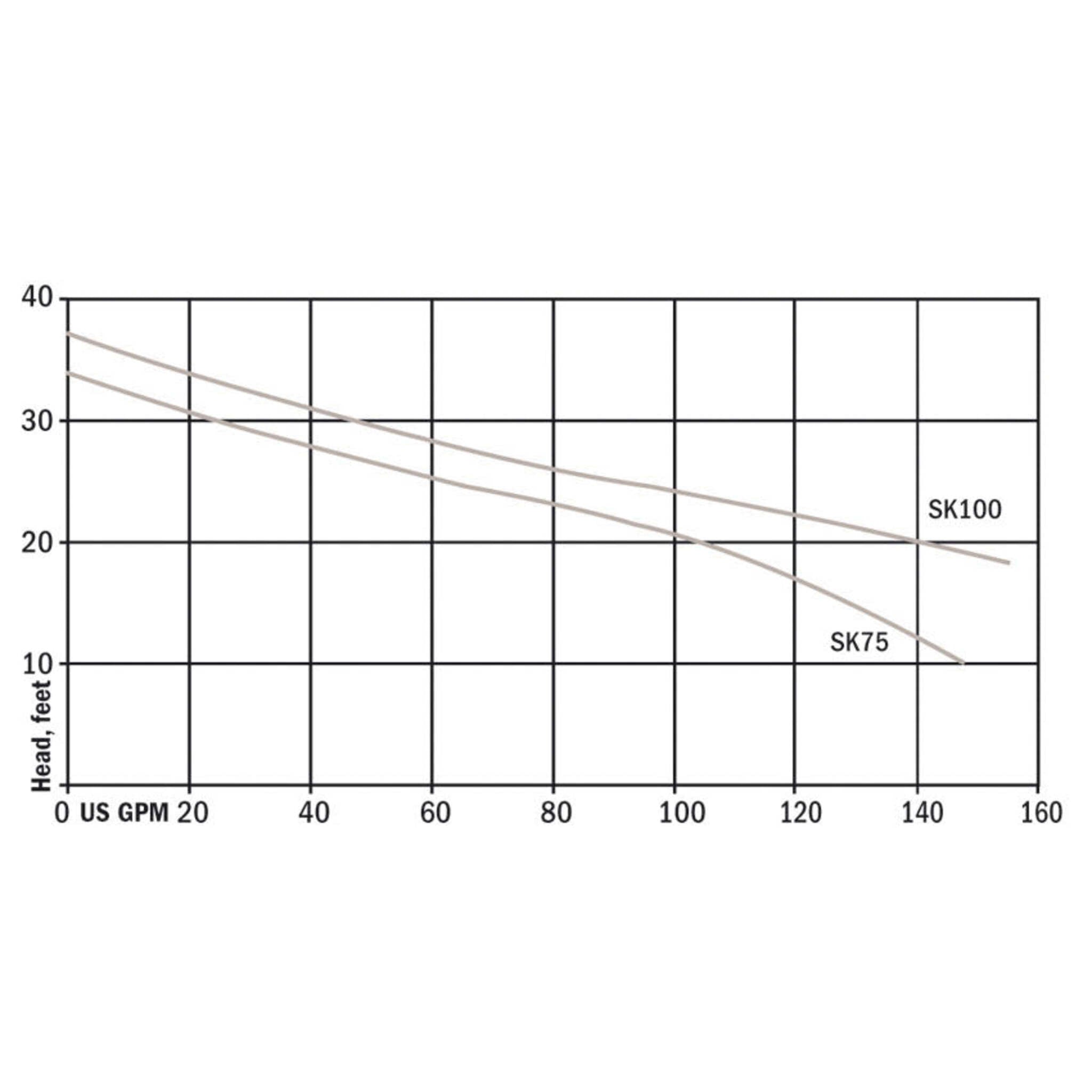

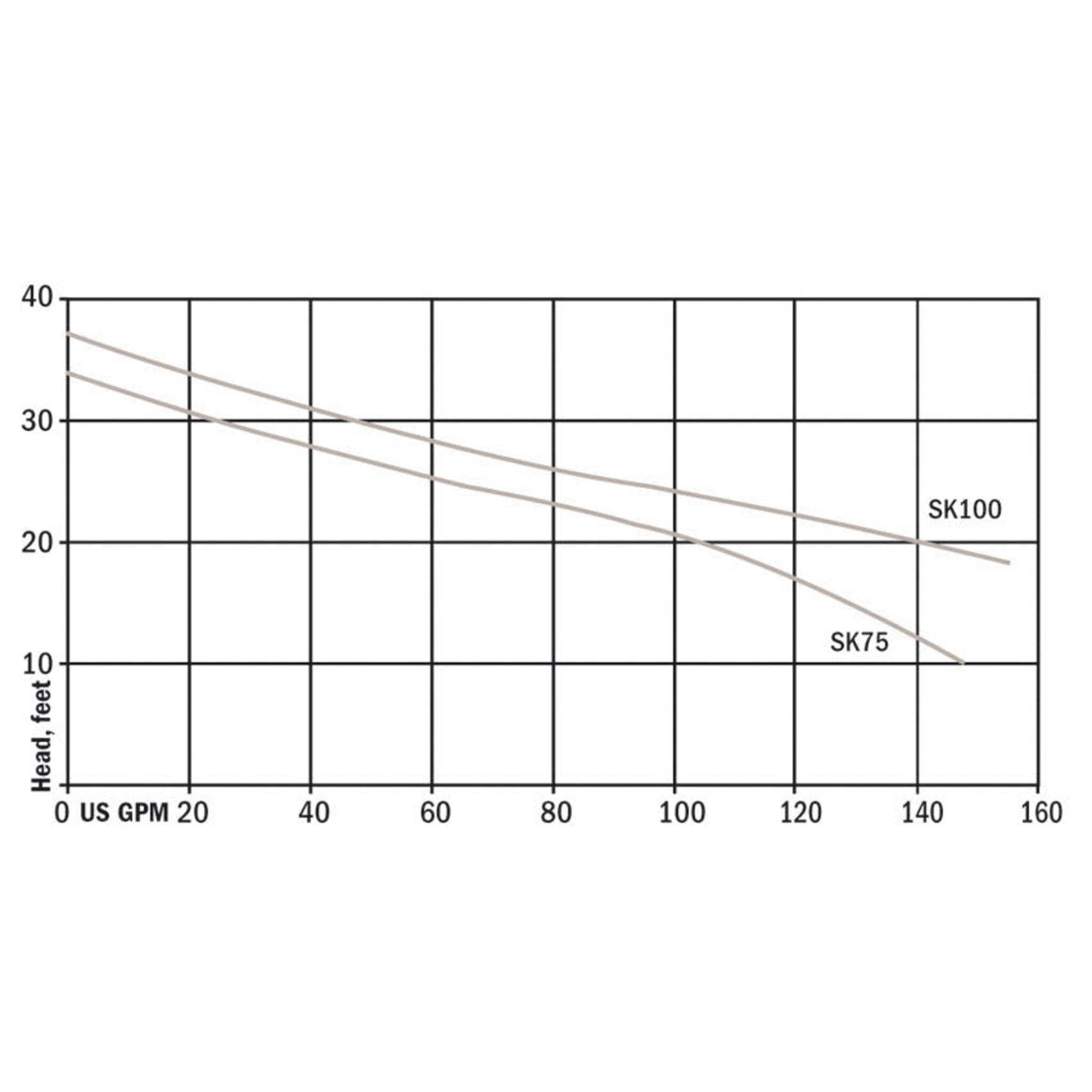

Choosing the right Hydromatic pump depends on factors like the type of fluid being pumped, the required flow rate, total dynamic head (TDH), and whether you need a grinder, sewage, or sump pump. Consulting a pump performance chart or speaking with a professional can help ensure you select the right model for optimal efficiency and longevity.

2. Can Hydromatic pumps be used for high-solids wastewater?

Yes, many Hydromatic pumps are specifically designed to handle high-solids wastewater. Their grinder pumps use powerful cutting mechanisms to break down solids before pumping, making them ideal for municipal, commercial, and heavy-duty residential applications.

3. What is the average lifespan of a Hydromatic pump?

The lifespan of a Hydromatic pump varies depending on usage, maintenance, and installation conditions, but with proper care, they can last 10 to 15 years or more. Regular maintenance, including cleaning and replacing worn parts, can significantly extend the pump’s longevity.

4. Why is my Hydromatic pump running but not pumping water?

If your Hydromatic pump is running but not moving water, the issue could be a clogged impeller, airlock, damaged seals, or a malfunctioning check valve. It’s important to inspect the pump and discharge line for blockages and ensure that the pump is properly primed.

5. How do I prevent clogging in my Hydromatic sewage pump?

To prevent clogging, avoid flushing non-biodegradable materials such as wipes, grease, and feminine hygiene products. Regular maintenance, including checking the impeller and cleaning out debris, will also help keep your pump running smoothly.