✅ This item is normally regularly stocked. Shipping times may vary depending on availability. Please contact us to confirm stock and shipping times. You will receive tracking details once the item has shipped.

Description

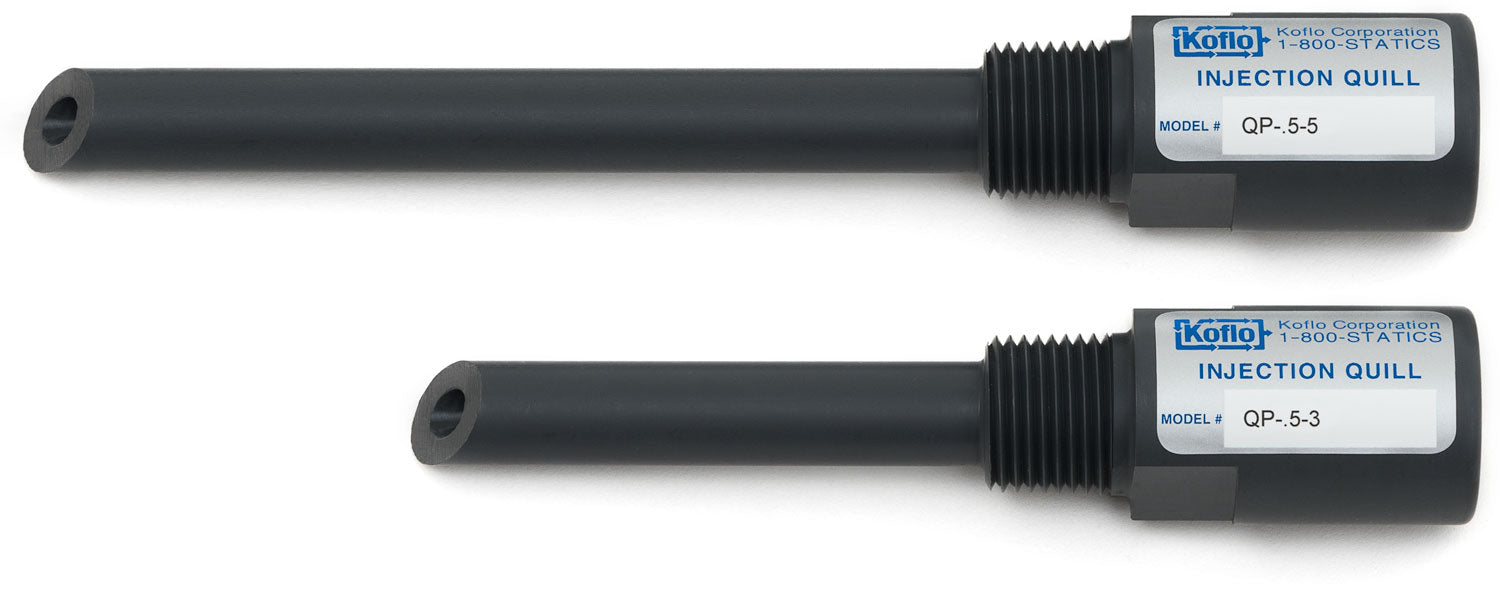

PVC Chemical Injection Quills with Viton®, Hastelloy & Ceramic Check Assembly for Accurate Chemical Feed

These PVC Chemical Injection Quills are engineered for reliable, corrosion-resistant dosing of treatment chemicals into pressurized pipelines. Built for municipal water treatment, wastewater facilities, industrial processes, and cooling tower systems, each quill delivers chemical solution directly into the center of the flow stream, improving mixing efficiency and preventing chemical attack on pipe walls.

Each quill features a spring-loaded Viton® check valve with a Hastelloy® spring and ceramic check ball, offering exceptional chemical resistance and long-term durability across a wide range of feed chemicals. The check assembly protects metering pumps and feed equipment by preventing pipeline liquid from backflowing into the chemical line.

Constructed from tough Schedule 80 PVC, these injection quills are rated for 150 PSI operating pressure and 140°F working temperature. They can be mounted in any direction—horizontal, vertical, or inverted—without restricting performance.

Connection layout is installer-friendly:

-

1/2" Injectors: 1/2" FNPT inlet × 1/2" MNPT process connection

-

3/4" Injectors: 3/4" FNPT inlet × 3/4" MNPT process connection

-

1" Injectors: 1" FNPT inlet × 1" MNPT process connection

These quills also accept 1/2" male × OD tube Kynar® fittings (sold separately), allowing installers to connect 1/4", 3/8", or 1/2" OD chemical feed tubing simply by selecting the appropriate fitting.

Available configurations include:

-

1/2" PVC quills – 3" or 5" stinger

-

3/4" PVC quills – 4" or 6" stinger

-

1" PVC quills – 5" or 8" stinger

Designed for versatility, durability, and accurate chemical placement, these quills are a dependable choice for chlorine feed, bisulfite injection, caustic dosing, pH correction, corrosion inhibitors, anti-scalants, odor control chemicals, and more.

Features of PVC Injection Quills with Viton®, Hastelloy & Ceramic Check Valve Assembly

-

Chemical-resistant check assembly using Viton® O-ring, Hastelloy® spring, and ceramic ball

-

Rated for 150 PSI and 140°F operating conditions

-

Multi-directional mounting—install vertically, horizontally, or inverted

-

Center-stream chemical delivery for improved mixing and reduced pipe wall attack

-

Schedule 80 PVC construction for excellent corrosion resistance

-

FNPT chemical inlet with MNPT stinger connection for direct threading into saddles or tees

-

Compatible with 1/2" male × OD tube Kynar® fittings for 1/4", 3/8", and 1/2" OD tubing (sold separately)

-

Available in 1/2", 3/4", and 1" sizes with multiple stinger lengths

Frequently Asked Questions (FAQs)

Can these injection quills be mounted in any direction?

Yes. They can be mounted horizontally, vertically, or upside down without affecting performance or check valve operation.

What pressure and temperature are these quills rated for?

They are rated for 150 PSI and 140°F, suitable for most municipal and industrial water systems.

What materials are used in the check valve assembly?

Each quill includes a Hastelloy® spring, ceramic ball, and Viton® O-ring, offering outstanding resistance to chlorine, acids, caustics, bisulfite, and other aggressive chemicals.

What thread connections do these quills use?

-

FNPT inlet for the chemical feed line

-

MNPT process connection for threading into a pipeline tapping, tee, or saddle

Sizes match the injector: 1/2", 3/4", or 1".

What tubing sizes can be used for the chemical feed?

By using a 1/2" male × OD tube Kynar® fitting (sold separately), you can connect:

-

1/4" OD tubing

-

3/8" OD tubing

-

1/2" OD tubing

What is the purpose of the stinger length?

The stinger ensures chemical is injected into the center of the pipe, maximizing mixing and preventing concentrated chemical attack on the pipe wall.

What chemicals are compatible with these PVC quills?

Common compatible chemicals include:

-

Sodium hypochlorite (chlorine)

-

Caustic soda

-

Acids (depending on concentration)

-

Sodium bisulfite

-

Corrosion inhibitors

-

Anti-scalants

-

Polymer solutions

Always confirm chemical compatibility with PVC and Viton®.

Where are these injection quills typically used?

-

Municipal drinking water treatment

-

Wastewater treatment plants

-

Cooling towers

-

Industrial process water

-

pH adjustment and corrosion control systems

-

Chemical metering skids

✅ This item is normally regularly stocked. Shipping times may vary depending on availability. Please contact us to confirm stock and shipping times. You will receive tracking details once the item has shipped.

Similar Products

Featured collection