✅ This item is normally regularly stocked. Shipping times may vary depending on availability. Please contact us to confirm stock and shipping times. You will receive tracking details once the item has shipped.

Description

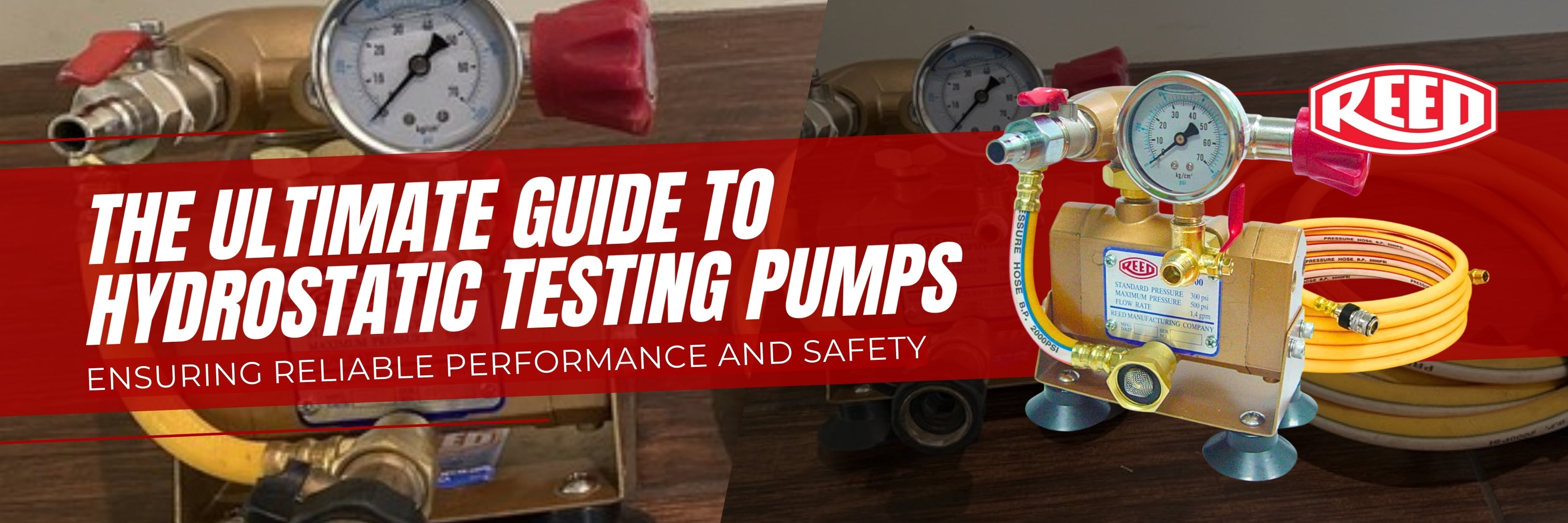

The Triple R HT454 Electric Hydrostatic Test Pump is a compact, professional-grade pump designed for controlled hydrostatic pressure testing of water-based systems. It is built to pressurize closed systems accurately, hold pressure reliably, and support inspection, commissioning, and maintenance work where pressure verification is required.

This electric hydrostatic test pump prioritizes pressure control and accuracy, not high-volume transfer, making it well-suited for plumbing, fire protection, and piping system testing.

Triple R HT454 Electric Hydrostatic Test Pump Specifications

| Specification | Details |

|---|---|

| Body | Anodized Aluminum |

| Plunger and Valves | Stainless Steel |

| Gauge | Liquid-Filled, Stainless Steel Case |

| Weight | 34 lbs |

| Dimensions (Unboxed) | 12″ × 12″ × 8″ |

| Motor | 1/2 HP Ball Bearing, 115V |

| Inlet / Outlet | 3/8″ Female NPT |

| Maximum Fluid Temperature | 140°F |

| Maximum Pressure | 400 PSI |

| Open Flow | 4.5 GPM |

| Seals | NBR |

| Voltage | 115V AC |

| Amps | 7.2A |

This hydrostatic pressure testing pump delivers sufficient flow to fill systems efficiently, then transitions to precise pressure generation and holding.

What This Electric Hydrostatic Test Pump Is Used For

The HT454 electric hydrostatic test pump is designed for pressure testing, not continuous pumping. Typical applications include:

- Plumbing system pressure testing

- Fire sprinkler and standpipe testing

- Pipe, valve, and fitting pressure verification

- Commissioning closed-loop water systems

- Maintenance and inspection testing

Its compact size and electric operation make it a practical pressure test pump for plumbing systems and field inspection work.

How the HT454 Electric Hydrostatic Test Pump Performs the Test

The pump connects to a filled water system and raises pressure gradually to the required test level. Once the target pressure is reached, the pump is shut off.

A built-in check valve in the discharge line allows the system to hold pressure without continuous pump operation. A liquid-filled pressure gauge provides clear, stable readings during the test hold period.

This design supports accurate testing while minimizing wear on the pump and electrical components.

Electric Hydrostatic Test Pump Mechanical Construction & Reliability

The HT454 is built for repeated field use with serviceable, corrosion-resistant components:

- Anodized aluminum pump body

- Stainless steel plungers and valves

- NBR seals

- Liquid-filled 600 PSI pressure gauge

- Silicon/carbon sealing components

These materials support long service life in professional testing environments where reliability and accuracy matter more than speed.

Portability & Included Kit Components

This electric hydrostatic test pump is supplied as a complete testing assembly, minimizing setup time on site.

Included components:

- 5 ft inlet hose with filter

- 10 ft discharge hose with quick disconnect and internal check valve

- Heavy-duty metal carry case with integrated handle

At 34 lb, the pump is easy to transport while remaining stable during operation, making it a portable electric hydrostatic test pump suited for jobsite use.

Application Limits (Important)

This pump is designed strictly for hydrostatic testing with water.

It is not intended for:

- Dry-run operation

- Chemical injection or aggressive fluids

- Continuous water transfer

- Fluids exceeding 140°F

- Operation without proper drainage in freezing conditions

Using the pump outside these limits may reduce service life or void warranty coverage.

Electric vs. Manual Hydrostatic Test Pumps

Compared to manual test pumps, the HT454 offers:

- Faster pressurization

- More consistent pressure control

- Reduced operator fatigue

- Improved accuracy for repeatable tests

Manual hydrostatic pumps remain suitable for low-volume or occasional testing, while this electric pressure testing pump is better suited for frequent professional use.

Triple R Hydrostatic Test Pumps at Cleanflow

Triple R hydrostatic testing pumps are designed for professional inspection and testing environments where pressure accuracy and reliability are critical. The HT454 reflects that focus through controlled performance, serviceable construction, and practical portability.

Cleanflow supplies the Triple R HT454 Electric Hydrostatic Test Pump along with technical support and replacement components. If you need assistance confirming specifications or selecting the correct hydrostatic testing solution, our team is available to help.

FAQs

What is an electric hydrostatic test pump used for?

An electric hydrostatic test pump is used to pressurize water-filled systems to verify strength, integrity, and leak-free performance during inspection and commissioning.

Can this pump hold pressure after shutdown?

Yes. An internal check valve allows the system to hold test pressure after the pump is turned off.

Is this pump suitable for fire sprinkler testing?

Yes. It is commonly used for hydrostatic testing of fire sprinkler and standpipe systems within rated pressure limits.

Does the pump require priming?

Yes. The system and pump must be filled with water before pressure testing to eliminate air.

How should the pump be winterized?

All water must be fully drained from the pump and hoses after use in freezing conditions.

Can this hydrostatic test pump be used for long pipe runs or large systems?

Yes, within reason. While the HT454 is compact and portable, it can effectively pressure-test larger systems as long as they are properly filled and purged of air. For very large volumes, fill time, not pressure capability, is the limiting factor.

What are hydrostatic test pumps used for?

Hydrostatic test pumps are used to pressurize water-filled systems to verify strength, integrity, and leak-free performance. They are commonly used for testing plumbing systems, fire sprinkler lines, piping networks, and other closed-loop water systems before commissioning or inspection.

✅ This item is normally regularly stocked. Shipping times may vary depending on availability. Please contact us to confirm stock and shipping times. You will receive tracking details once the item has shipped.

Similar Products

Featured collection