Categories

- Shop All (4975)

-

-

- Hi-Vis Chainsaw Safety (14)

- Hi-Vis Coveralls and Overalls (10)

- Hi-Vis Hoodies and Shirts (27)

- Hi-Vis Jackets (30)

- Hi-Vis Pants (14)

- Hi-Vis Rain Wear (30)

- Hi-Vis Vests (36)

- Winter Hi-Vis Bombers and Parkas (18)

- Winter Hi-Vis Coveralls and Overalls (18)

- Winter Hi-Vis Hoodies (3)

- Winter Hi-Vis Pants (3)

- Winter Hi-Vis Vests (5)

-

-

-

-

- Brooms (2)

- Dust Mops (0)

- Dust Pans and Brushes (4)

- Flow Thru Tools (2)

- Microfiber Mops (0)

- Pool and Tank Tools (2)

- Scrubbers and Scrapers (1)

- Soap and Sanitizer Dispensers (0)

- Sprayers (1)

- Squeegees (1)

- Toilet Brushes and Plungers (3)

- Trash Cans & Bags (8)

- Wet Floor Signs (0)

- Wet Mops and Buckets (4)

-

- Bars and Prying Tools (21)

- Bolt Cutters and Shears (17)

- Chisels and Punches (9)

- Combination Hand Tool Sets (12)

- Extractors (13)

- Files (6)

- Gear Pullers (14)

- Hammers and Mallets (14)

- Hand Saws (17)

- Hex Keys (12)

- Layout and Distance Lasers (1)

- Marking Tools (0)

- Measuring Tools (10)

- Pliers (52)

- Precision Measuring and Testing Tools (24)

- Propane Torches (5)

- Screwdrivers and Nutdrivers (21)

- Sockets (66)

- Tap and Die Sets (11)

- Tool Boxes (26)

- Utility Knives (14)

- VDE Tools (7)

- Wire Cutters and Strippers (14)

- Wrenches (22)

-

- Beveling and Deburring (17)

- Curb and Valve Keys (20)

- Drilling and Tapping (12)

- Extended Impact Sockets (3)

- Flaring and Rerounding (7)

- General Pipe Working Tools (19)

- Guillotine Pipe Cutters (2)

- Hydrostatic Test Pumps (14)

- Internal Pipe Cutters (6)

- Manhole Testing (4)

- PE Peelers (8)

- Pipe Reamers (4)

- Pipe Threading (17)

- Pipe Wrenches (24)

- Plastic Pipe Joint Kits (4)

- Plastic Pipe Saws (5)

- Power Drive (13)

- Quick Release Cutters (15)

- Ratchet Shears (9)

- Ratcheting Wrenches (12)

- Rotary Cutters (3)

- Shut Off Tools (9)

- Soldering Torches (3)

- Vises (7)

-

- Angle Grinders (6)

- Batteries and Chargers (18)

- Bench Grinders (7)

- Circular Saws (3)

- Combo Tool Kits (10)

- Cordless Fans (6)

- Cordless Lighting (15)

- Cut Off Saws (4)

- Drills and Drivers (8)

- Grease Guns (3)

- Impact Drivers (5)

- Jobsite Radios and Speakers (8)

- Lifestyle (6)

- Mitre Saws (2)

- Reciprocating Saws (4)

-

- Angle Grinder Wheels and Brushes (21)

- Bench Grinder Wheels (7)

- Circular Saw Blades (11)

- Drill and Driver Bits (26)

- High Speed Gas Saw Blades (3)

- Holesaws (11)

- Impact Sockets (25)

- Jig Saw Blades (2)

- Oscillating Multi Tool Blades (1)

- Portable Chop Saw Blades (4)

- Power Tool Storage (5)

- Reciprocating Saw Blades (8)

-

-

-

-

- Air Fresheners (0)

- All Purpose Cleaners (19)

- Bowl and Washroom (8)

- Coffee and Breakroom (19)

- Degreasers (3)

- Dishwashing (4)

- Disinfectants and Sanitizers (1)

- Drain Openers (7)

- Hand Cleaners (8)

- Laundry Cleaners (9)

- Paper Products and Wiper Rags (18)

- Scale Removers (4)

- Urinal Pucks and Liquids (5)

- Wet Wipes (2)

-

-

- Ball Valves (13)

- Black and Galvanized Steel Fittings (16)

- Bronze Pipe Fittings and Nipples (13)

- Butterfly Valves (4)

- Check Valves (18)

- Flexible Connectors (4)

- Gate and Globe Valves (5)

- Knife Gate Valves (9)

- Pipe Fitting Accessories (4)

- Schedule 80 PVC Fittings (27)

- Stainless Steel Fittings and Valves (24)

- Victaulic Grooved Fittings (22)

Reed - Pipe Threading

11 products

Showing 1 - 11 of 11 products

What Makes Reed Pipe Threading Tools Stand Out?

Reed has been a leader in pipe threading tools since 1896, providing high-quality solutions for professionals in the water and wastewater industry. Their extensive product lineup includes durable pipe cutters, precision threaders, and specialized tools for pipes, ensuring efficiency and reliability in plumbing, irrigation, and industrial applications. With a legacy of innovation and craftsmanship, Reed continues to set industry standards, offering essential tools that meet the demands of modern infrastructure projects.

Why Choose Reed - Pipe Threading?

Reed is known for pipe threading because of its durable, high-performance threading tools designed for precision and efficiency. Reed offers a wide range of threading solutions, including manual and power-driven machines, compatible with various pipe materials. Their tools are known for long-lasting quality, ease of use, and industry-leading innovation, making them a trusted choice for professionals seeking reliable and accurate pipe threading solutions. Check out their popular products below:

-

Reed Enclosed Pipe Threader Dropheads

-

Reed Enclosed Pipe Threader Dropheads offer a versatile and efficient solution for NPT pipe threading, seamlessly integrating with the REED 601PD power drive and various major brands like RIDGID®, Super Ego®, Virax®, and Rothenberger™. Designed as disposable, enclosed units, they eliminate the need for die segment replacements while ensuring ease of use and minimal maintenance.

-

Reed DH84-7 Enclosed Ratchet Threader Set 1-1/4" to 2"

-

The Reed DH84-7 Enclosed Ratchet Threader Set 1-1/4" to 2" offers long-lasting performance while remaining lightweight and portable for easy transport. The enclosed dropheads prevent alignment issues, and the cost-effective design eliminates the need for individual segment replacement. Compatible with various power drives, this set includes three dropheads (1-1/4", 1-1/2", and 2" NPT) and comes in a reinforced carrying case for organized storage.

-

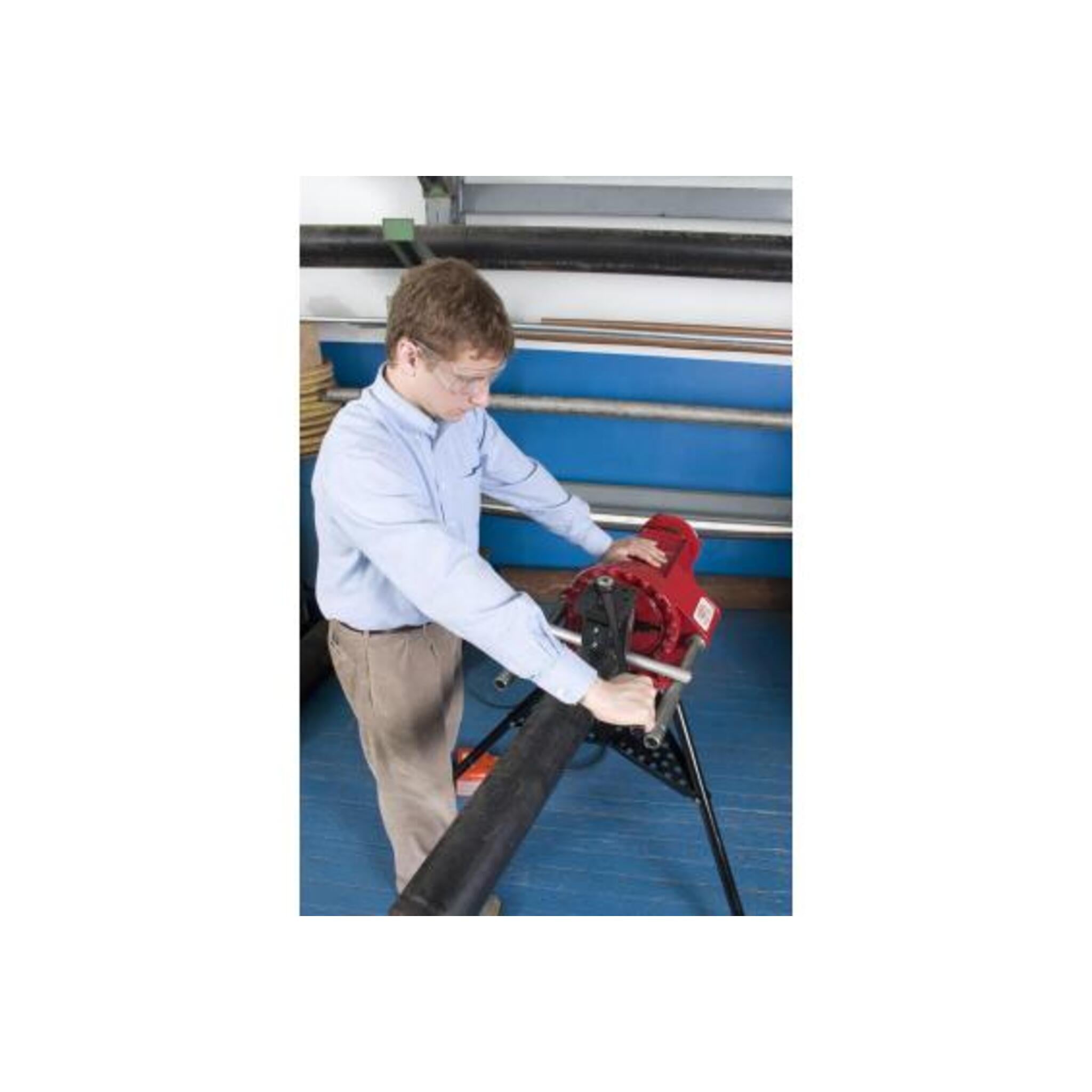

Reed RG6S Portable Roll Groover for 5301PD Power Drive

-

The Reed RG6S Portable Roll Groover for 5301PD Power Drive ensures accurate and efficient pipe grooving. Capable of handling steel, stainless steel, aluminum, and PVC pipes ranging from 1-1/4” to 6” in diameter, it delivers consistent grooves that meet mechanical coupling system specifications.

FAQs

1. What is the difference between NPT and BSP pipe threading?

NPT (National Pipe Thread) and BSP (British Standard Pipe) threads differ mainly in their design and compatibility. NPT threads are tapered, creating a tighter seal by wedging together, while BSP threads can be parallel or tapered. Since they have different angles and pitch, they are not interchangeable, and using the wrong type can lead to leaks or fitting issues.

2. Why do plumbers use pipe threading instead of welding?

Pipe threading is often preferred over welding because it allows for easier disassembly, maintenance, and modifications. It is also more cost-effective for smaller projects and can be done on-site with portable threading tools, unlike welding, which requires specialized equipment and skills.

3. What tools do I need for manual pipe threading?

For manual pipe threading, you typically need a pipe cutter, reamer, pipe wrench, threading die, and a ratcheting threader. Using a good-quality cutting oil is also crucial to reduce friction and extend the lifespan of your tools.

4. Can I use a pipe threading tool on PVC or plastic pipes?

No, pipe threading tools are designed for metal pipes like steel, iron, or brass. PVC and plastic pipes are usually joined with solvent welding or compression fittings, as threading them can weaken the material and lead to leaks.

5. How do I prevent my pipe threading dies from wearing out quickly?

To extend the life of your pipe threading dies, always use high-quality cutting oil to reduce friction and prevent overheating. Regularly clean the dies after use, avoid excessive force when threading, and ensure they are properly stored in a dry place to prevent rust.